“We cut downtime by 60% in one quarter. That’s millions saved.”

“We don’t guess anymore. We standardize, we measure, we improve.”

“What took three teams a week now takes one person one day.”

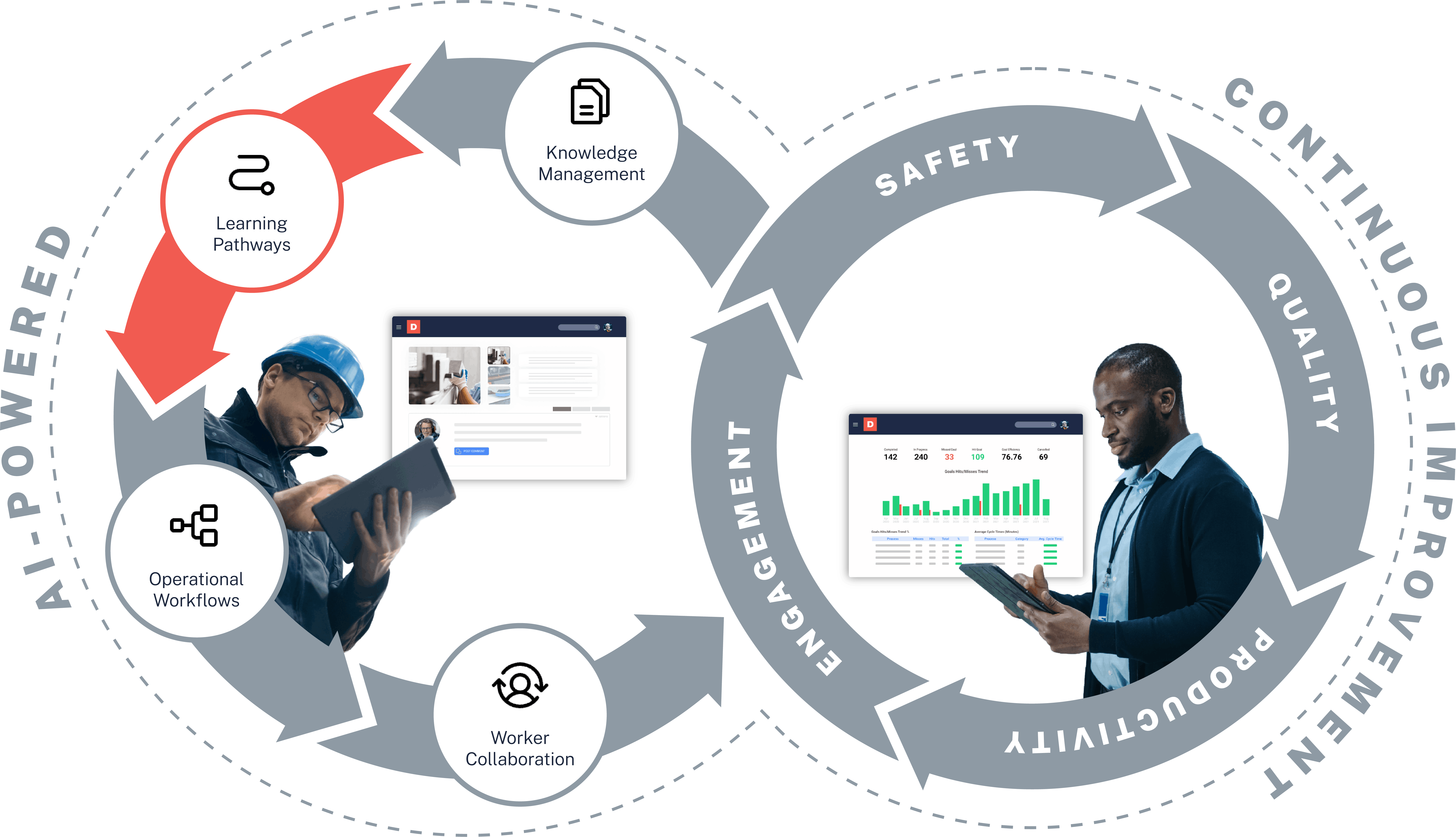

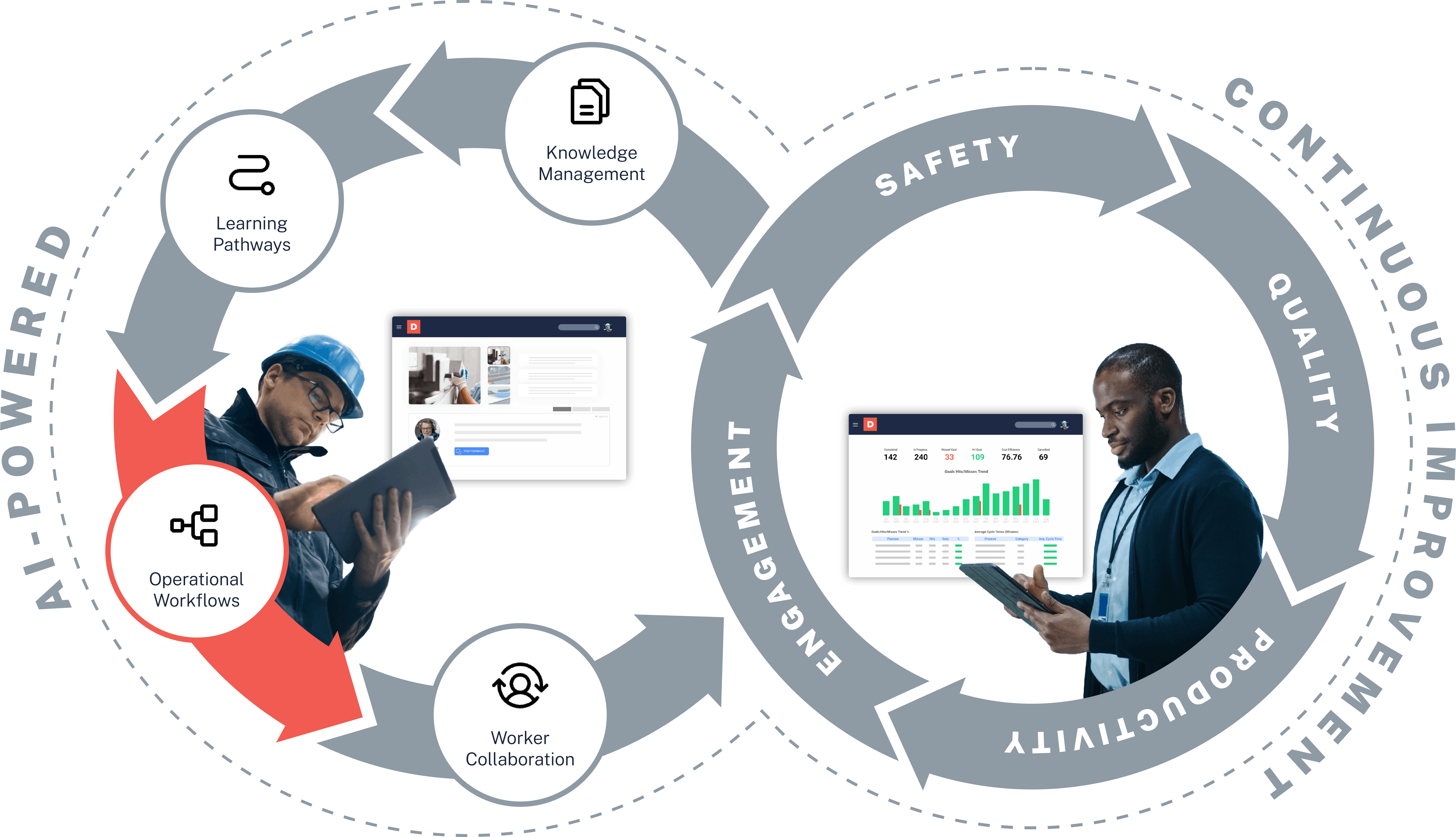

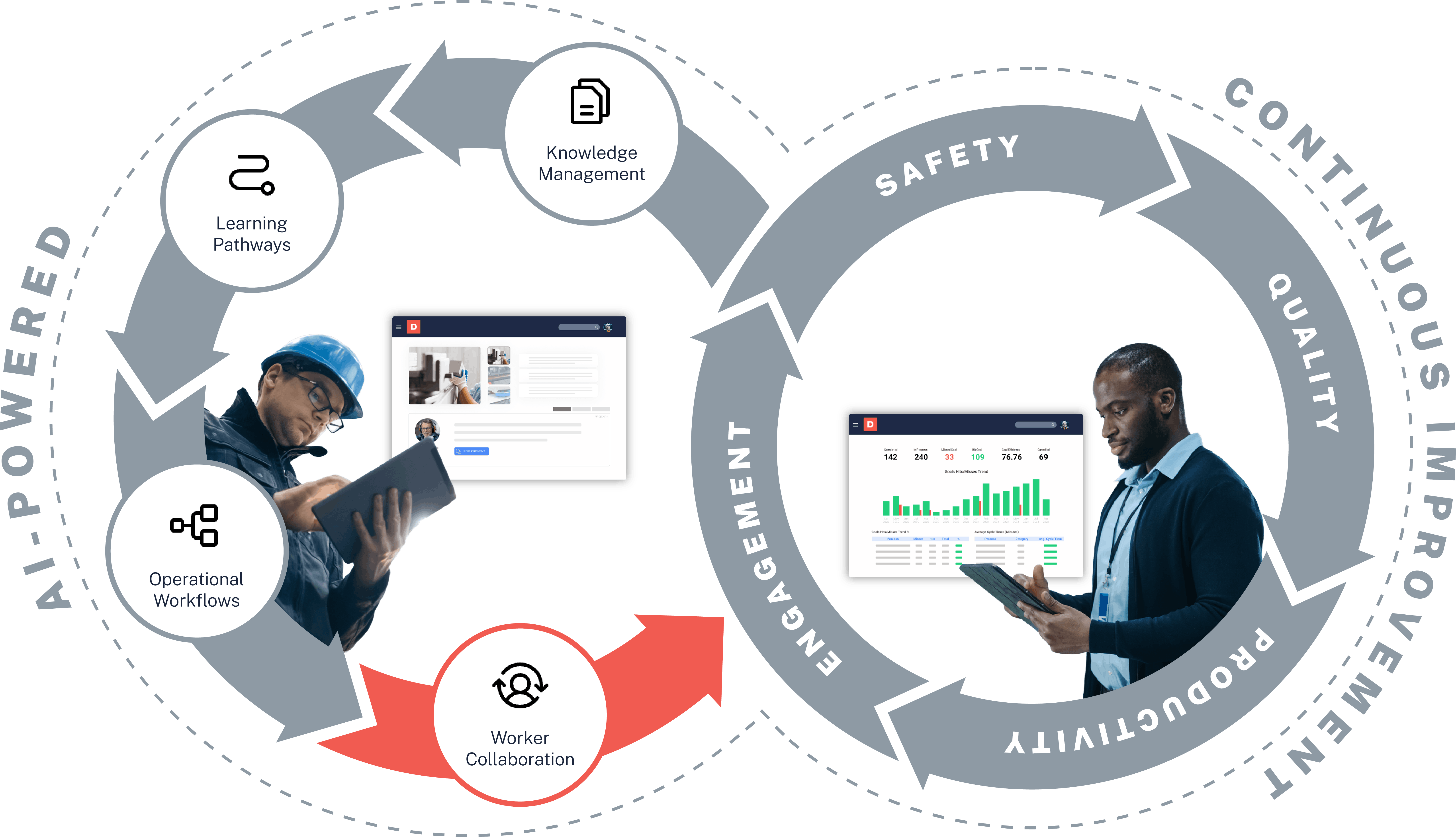

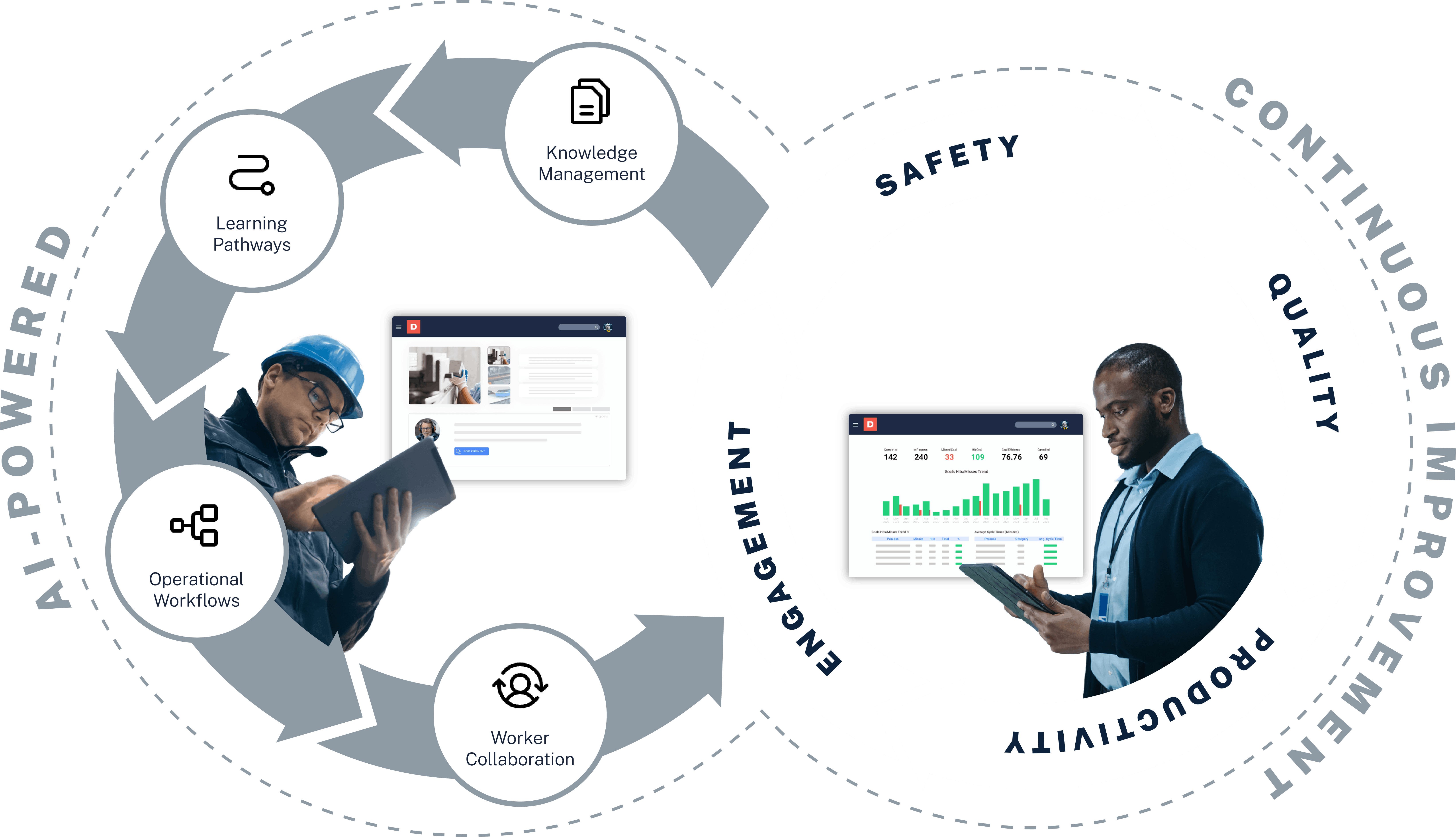

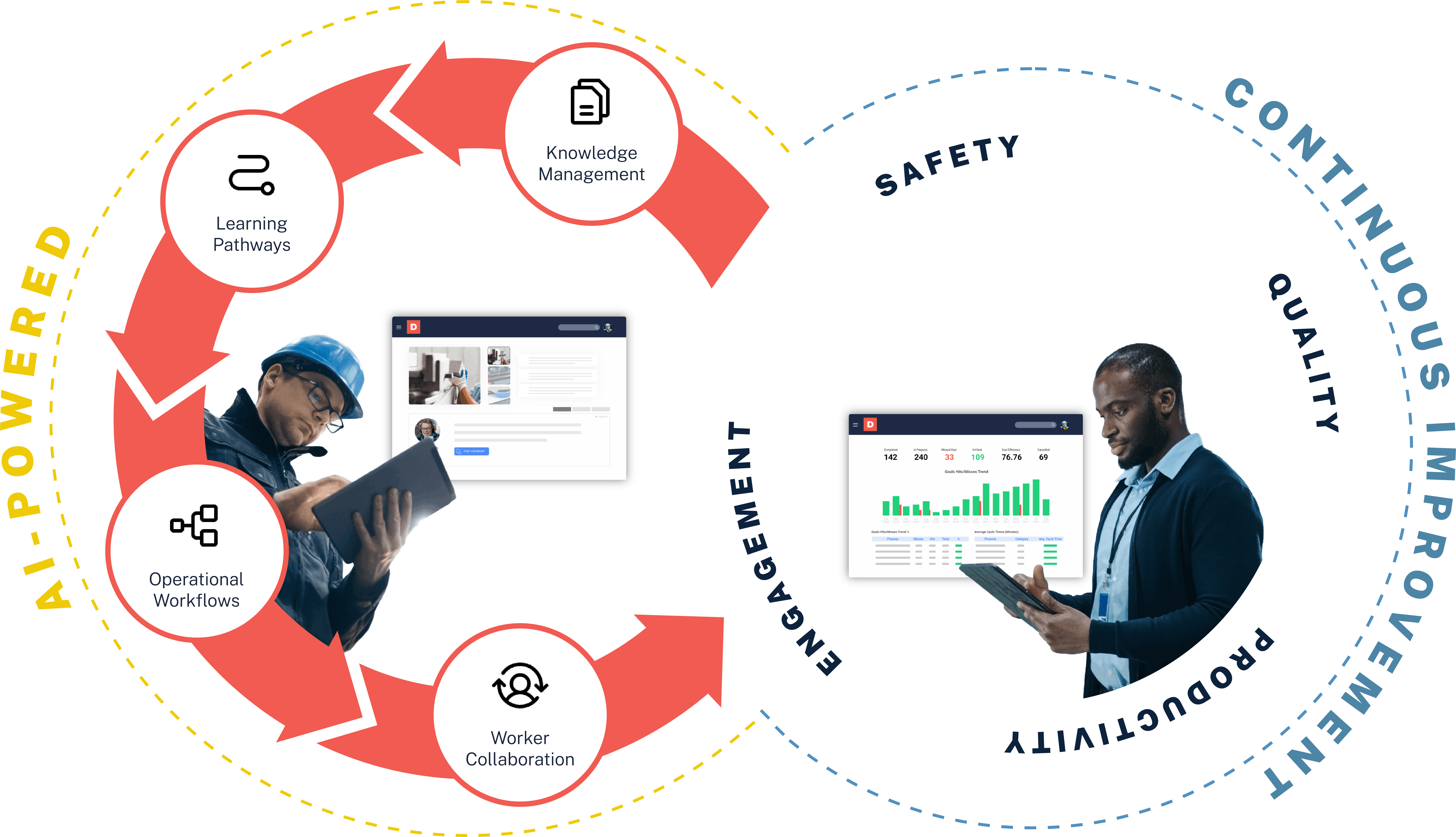

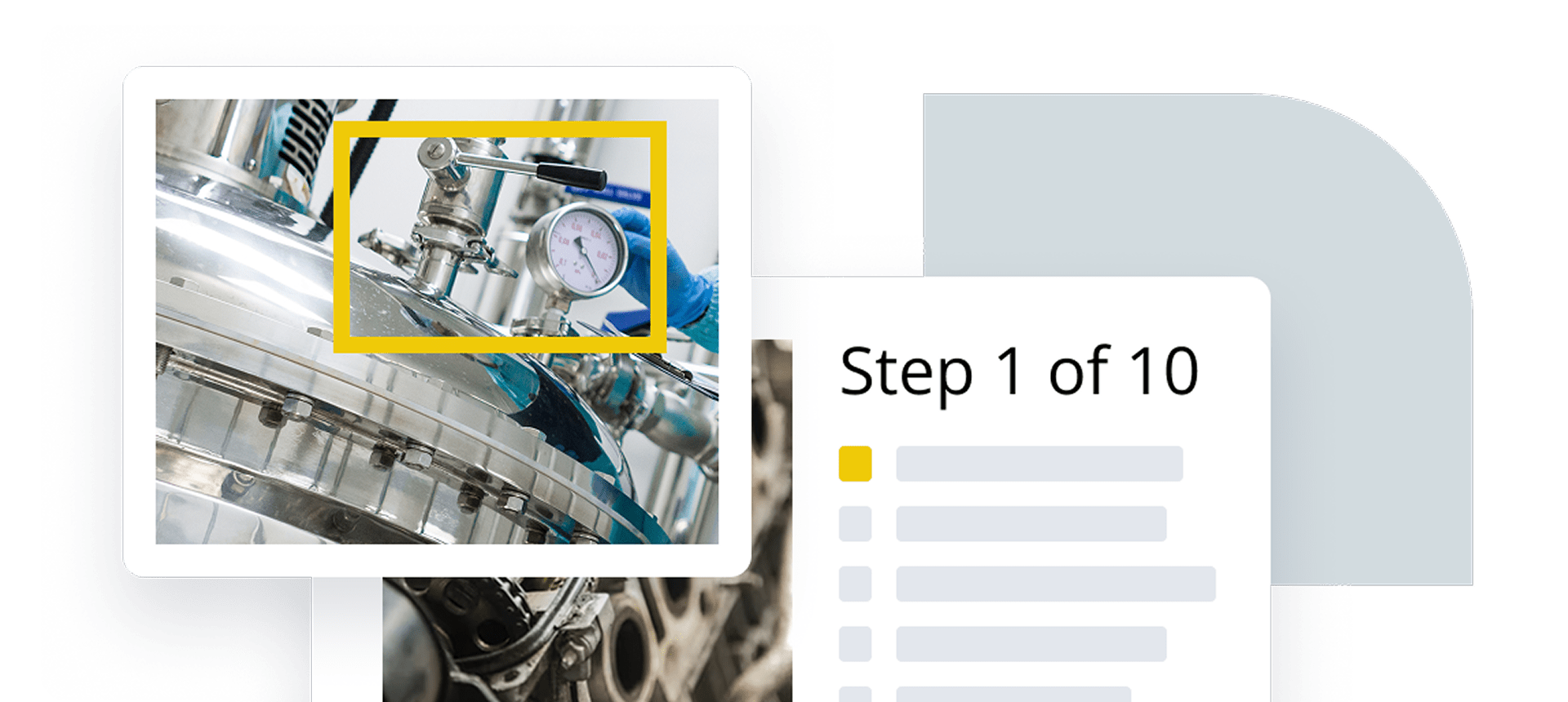

Rolling out process documentation across global sites used to take years. Teams struggled with outdated SOPs, inconsistent formatting, and siloed training tools that made standardization nearly impossible.

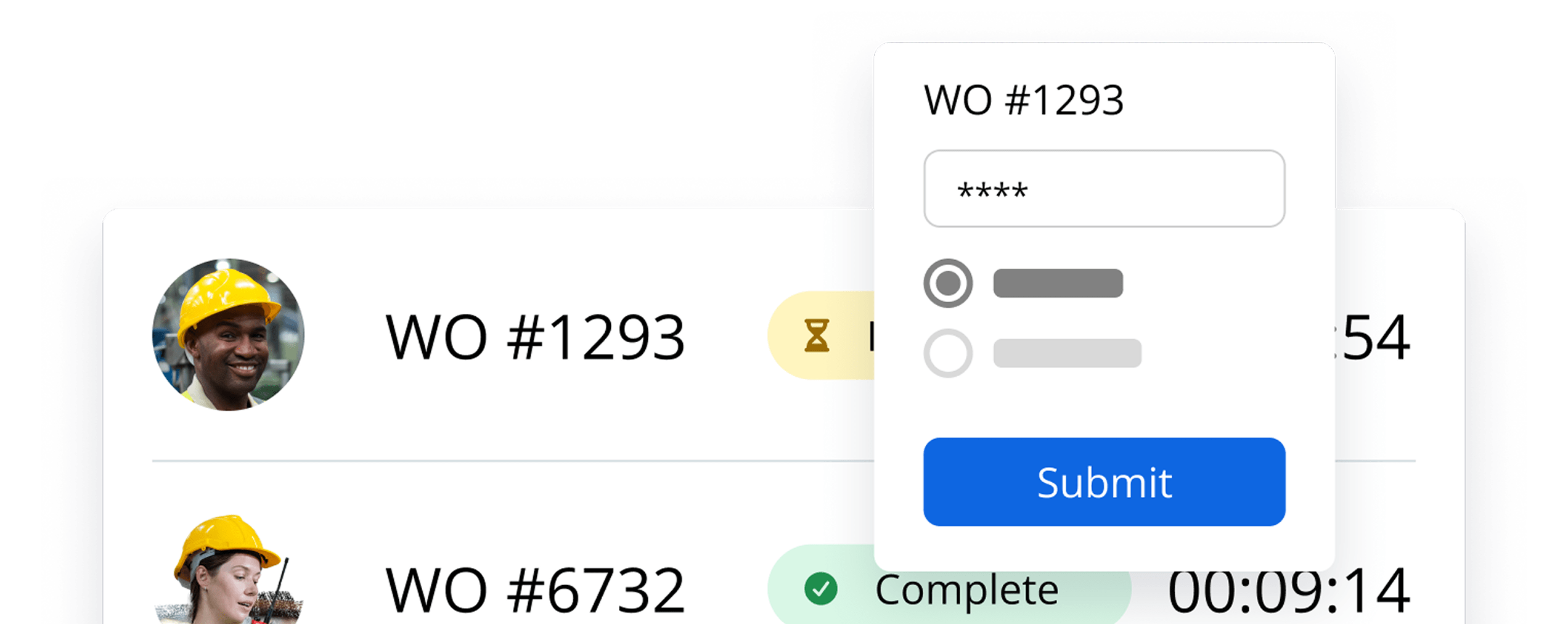

With Dozuki and CreatorPro AI, this company digitized tribal knowledge at scale, launching standardized documentation and training across over 100 facilities in a matter of months. The connected approach has transformed how knowledge is shared, skills are tracked, and processes are improved globally.

Facing high turnover and inconsistent onboarding, this leading food manufacturer digitized its tribal knowledge and embedded it into structured, role-based training. Standard work was transformed into clear, visual guides, all accessible on the floor and aligned with how real work gets done.

As a result, time-to-readiness dropped by over half. New hires reached the floor faster and safer, while managers gained full visibility into training progress, skill gaps, and compliance across teams.

To support rapid expansion into a new 750,000 sq. ft. facility, Airstream overhauled its outdated training program with Dozuki. By replacing paper-based systems and tribal knowledge with digital standard work, the team created structured onboarding and job-specific training tied directly to real tasks.

Turnover dropped by 83%, and trainer bandwidth improved as new hires gained clarity and confidence from day one. Training became consistent, measurable, and aligned with operations, setting the stage for long-term workforce development and shop floor success.