Continuous Improvement

9 min read

A Quick 5 Step Guide to Lean Product Development

In the fast-paced world of product research and development, lean methodology can help reduce waste and shorten delivery times. This guide outlines five quick steps to bring lean principles to your new product development (NPD), improve the bottom line, and create sustainable development practices for years to come.

Although traditionally applied in manufacturing environments, lean methods can be applied to any industry, because all businesses benefit from cycle time improvements, increased productivity, cost savings, and more. To begin, there are five guiding principles in lean development:

"For most products, 65-75% of the total cost of the product is determined before it even gets to the factory." - John Drogosz 1

1. Specify value for your customers

2. Identify and focus on your value stream

3. Create flow by eliminating waste

4. Respond to customer pull

5. Pursue perfection through repetition

1. Specify Value for Your Customers

It’s important to note that to create a successful and sustainable lean operation, value comes first.

Before product development begins, look at the existing market and work backwards to make sure you have the product your customers will ultimately buy. This “Market Back” approach allows you to focus on investing in winning products before production even begins.

"Companies that place cost reductions ahead of value creation when implementing lean principles usually see their lean efforts fall flat."

-Norbert Majerus, Senior Master Black Belt, Goodyear2

“Customer” isn’t always a universal term. Depending on your product development path, your customer could differ between internal customers (those who work at your organization) and external customers (those who will buy your product).

A surefire way to find what your customers find valuable and will ultimately buy is to try a lot and evaluate fast. This involves discarding losers quickly, not wasting precious time attempting to make a loser a winner, and staying ahead of your competition by being extremely agile in all approaches.

Your biggest challenge might be convincing stakeholders to put delivery before efficiency. Because if you don’t have the right product at the right time for customers, it doesn’t matter how efficient your development is.

Once value is specified your teams must remain focused on the processes, otherwise known as the value stream.

2. Identify and Focus on Your Value Stream

Product development affects your organization’s entire ecosystem. To ensure a product can be successfully brought to market, it’s important to think end-to-end and make sure all the company’s players know their roles. Engineers, manufacturers, sales teams, marketers, and more - when everyone knows their role in the value stream, organizations run much smoother.

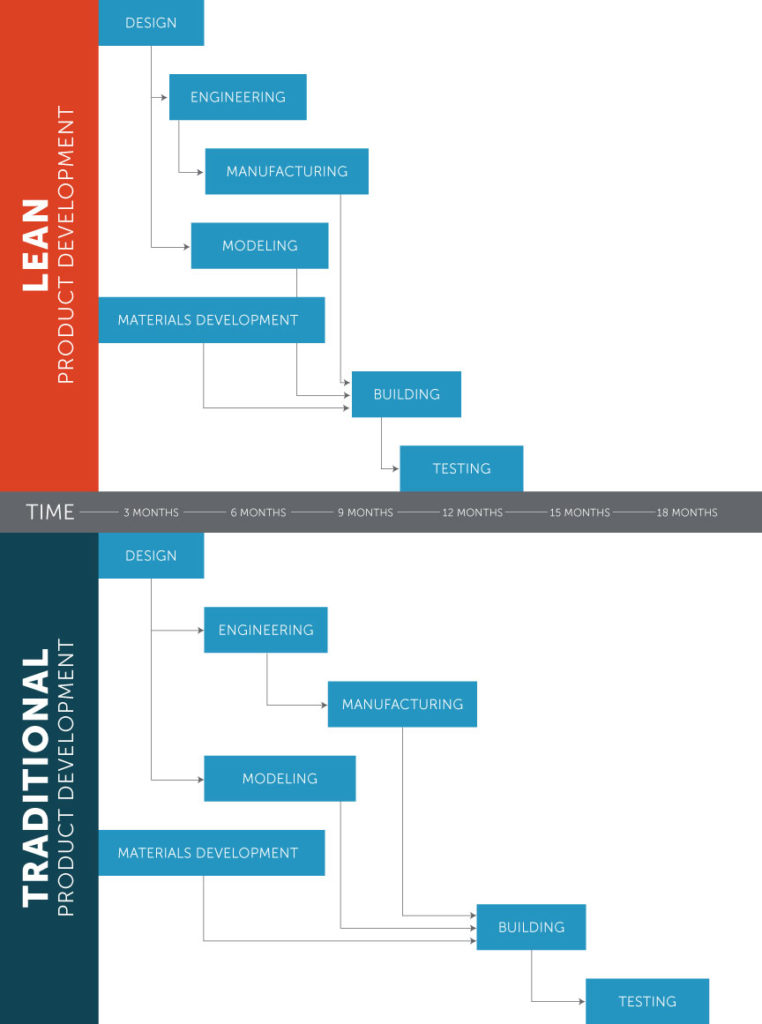

Traditional development cycles involved multiple ‘hand-offs’ between departments, causing numerous communication errors and little room for identifying improvements. Once a product was developed in R&D it was then passed off to manufacturing where it became their problem to execute.

Lean product development turns this approach on its head, and for good reason. With lean, stakeholders are engaged and united from day one - no hand-offs, no surprises - aligning everyone behind a common goal.

Collaboration in the early stages of a project reduce the number of negative impacts and holdups that can happen down the line as progress continues. Getting manufacturing involved ahead of time allows for problems to be identified and resolved early, before they cause deliverability issues later.

"80% of business failures can be traced to the way in

which products are developed."

Colin Mynott3

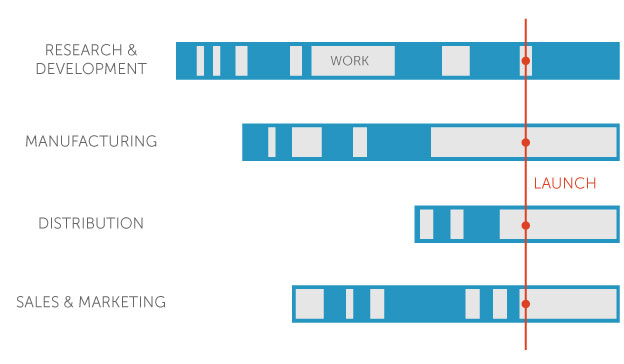

To best visualize this, illustrating concurrent development plans can help. You’ll notice that R&D doesn’t fall back early in this plan. By staying involved throughout the launch, problems can be identified in the marketplace and resolved quickly - all while maintaining a laser focus on providing value for your customers.

Focusing on value not only helps your teams eliminate steps that don’t create value, they also reduce waste and lead directly into the next step in your lean process - flow.

3. Create Flow by Eliminating Waste

The lean company always wants processes and value streams to flow faster and faster, but why? If processes flow then customers are served faster, lead times are shorter, product quality is improved, you become more flexible, the list goes on.

Most importantly, a faster flow equates to a lower product cost.

A lean organization realizes that the cost of a product is primarily driven by the rate of flow through the value stream. What needs to be done to make things flow faster? Begin by studying the process to understand what adds value and what doesn’t, and what tasks can be accomplished at the same time without waiting on dependencies.

4. Respond to Customer Pull

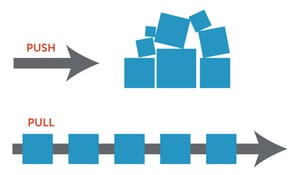

To make product development flow faster, understanding customer pull is essential. Pull is the need to buy a product (customer demand) the lens through which flows are viewed and evaluated for ongoing improvements.

When waste is removed, flow is improved, and you are positively impacting the experience of customers through better efficiency, freeing up time to work on things that deliver more value. It’s important to note that pull is not the same as rushing through processes. But rather, it allows you to quickly respond to customer needs through a more focused work environment.

In order to be prepared to respond to pull, your organization must be listening at all times to be in-tune with processes and production information. These investments can greatly help in managing cash flow.

"We have to make sure the customer has the right product."

-Norbert Majerus, Senior Master Black Belt, Goodyear

When less money and space are tied up in raw goods your organization can be better prepared to respond quickly the pulls of your customers and use your improved flows for more efficient results. Time spent validating the demand (pull) and responding efficiently (flow) on behalf of customers can also remove dependencies on forecasting and guesswork for future endeavors.

5. Pursue Perfection Through Repetition

The cornerstone of successful lean product development is repetition. As value is defined, value streams are established, waste is removed, and both flow and pull are introduced, it’s time to begin the process again until a state of perfection is reached, creating measurable value with no waste.

Lean product development principles allow you to have it all - the delivery, the speed, the efficiency, and the quality. But throughout the product development cycle, if you aren’t focused on the bottom line, it will be much harder to make a business case for your lean initiative. Maintain management approval for lean product development by making sure to see and track your results after implementation!

Luckily, as you refine your processes the results will follow and your customers will realize the benefits.

More Lean Product Development Tools

James Morgan and Jeffrey Liker, authors of The Toyota Product Development System, Integrating People, Process and Technology, cite aligning organizations through simple visual communication and standardized learning tools as the final principles of lean product development. 4

Learn more about how to adopt lean principles at your organization, in our conversation with Lean Six Sigma Senior Master Black Belt Norbert Majerus. In it, you’ll learn how Mr. Majerus successfully implemented lean product development at the Goodyear Tire Company. Watch the full conversation with Norbert Majerus.

1. http://www.industryweek.com/blog/lean-product-and-process-development

2. https://www.dozuki.com/resources/webinar-lean-product-development/

3. Mynott, Colin. Lean Product Development: A Manager’s Guide. London: The Institution of Engineering and Technology

4. http://www.industryweek.com/companies-amp-executives/13-principles-lean-product-development

Topic(s):

Continuous Improvement

Related Posts

View All Posts

Continuous Improvement

How to Establish a Lean Culture in 4 Steps

5 min read

An effective lean culture aims to reduce waste and inefficiency while improving the value delivered to customers. The lean organization is a model that’s been historically...

Continue Reading

Continuous Improvement

What is Standard Work?

6 min read

Lean operations and manufacturers have used Standard Work for decades, yet many companies lack clarity when it comes to this fundamental lean methodology. How is Standard...

Continue Reading

Continuous Improvement

A Lesson in Lean Manufacturing From the North Pole

4 min read

If Santa Claus ran a toy company, he’d have the best lean manufacturing operations in the industry. A lean analysis shows that he delivers custom tailored products to every...

Continue Reading