Training

6 min read

What Chipotle Taught Us About Training Standards

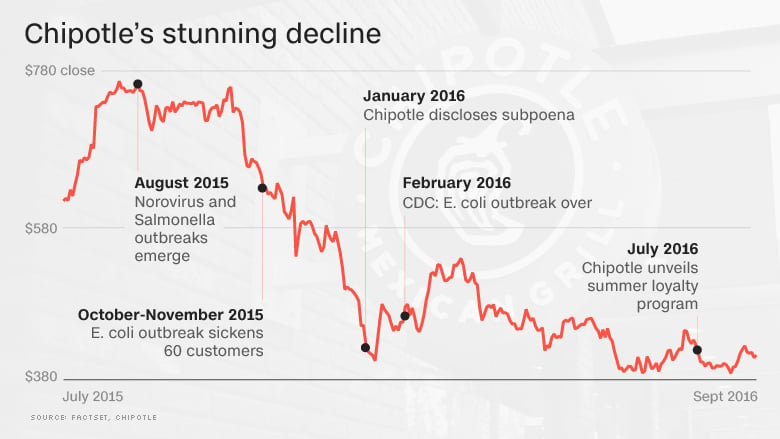

Chipotle, the Mexican food chain, has been in the spotlight recently for a variety of reasons. Unfortunately, not all coverage has been “good press.” A string of food safety scares has caused customers to lose trust and stock prices to fall. The missing ingredient?

Standardized training.

Chipotle’s History with Food Safety

Chipotle Mexican Grill seemed to be on the mend after suffering a colossal financial hit due to a series of high-profile food safety lapses in 2015. Unfortunately, it wasn’t just one episode that bruised the company’s reputation. A series of similar incidents caused over 100 customers to get sick with E. coli and salmonella over the past decade.

- A Chipotle in La Mesa, CA was linked to a hepatitis outbreak that infected 22 customers in 2008.

- An investigation in 2009 linked a Minnesota Chipotle to an outbreak of campylobacteriosis.

- A norovirus outbreak in 2017 was caused by a Chipotle chain in Virginia.

- A 2018 clostridium perfringens outbreak linked to a Powell, OH Chipotle, affecting over 700 people.

Were these outbreaks merely flukes that were out of Chipotle’s control, or could they have been prevented?

Success Wrapped in a Tortilla

Originally catapulted to success by the influx of investing capital by the McDonald’s corporation, Chipotle became widely popular due to its public image of clean, healthy food, with a Mexican flair. The company implemented a no-GMO policy for its ingredients while their CEO claimed that the restaurant’s food was “ethically and naturally” produced.

In 2006, McDonald's divested its controlling interest when Chipotle went public. The IPO saw the stock rise from $42 a share to $650 per share with the wild crescendo continuing. By the third quarter of 2015, Chipotle’s revenues had reached $1.2 billion, a whopping 639% increase in just over 10 years. The company was still enjoying a great ride, that is until the outbreaks began.

Standards in the Danger Zone

The Centers for Disease Control and Prevention (CDC) tested stool samples of some of the 700 customers reporting being ill after eating at an Ohio Chipotle in July 2018. The samples tested positive for Clostridium perfringens, a bacteria that, according to a recent New York Post article, “Thrives at temperatures between 40 and 140 degrees Fahrenheit — a range known as the ‘danger zone’ among food safety experts.”

Additionally, at other Chipotle’s, including the Ohio store, health officials found that lettuce and beans were not being properly cooled and warmed. Inspectors found boxes of raw chicken “leaning on other packaged foods,” according to a Business Insider report.

The CDC has confirmed that the root cause for hundreds of Chipotle customers — sick with symptoms of fever, diarrhea, nausea, pain, and weakness — was a lack of proper handling of food products and training of the company’s employees.

Solving Food Safety with Better Training Standards

Food safety is obviously a serious issue. Customers need to know that what they are eating is safe for them and their families. But food safety is also a deep concern for restaurant owners and managers trying to compete in a volatile market. A study conducted by the Journal of Extension found that approximately 72% of food service managers said they would be more likely to hire workers trained to current food safety standards. Additionally, 50% would be willing to pay higher wages to those already trained.

72% of food service managers said they would be more likely to hire workers trained to current food safety standards.

But what about training current employees? Because of the high turnover rate in the restaurant industry, it is imperative that training materials be created that are easily accessible, intuitive to use, and capable of consistently reinforcing training standards. This can be accomplished by either using digital training tools or developing products that can easily be used by today’s restaurant employees, which are currently millennials.

Five Steps for Successful Training

There is an obvious need to create food safety training materials that not only cover practices related to food temperature, utensil usage, product handling, proper cleaning and sanitizing, and general food safety principles — but also address the need for a program that provides consistent training that addresses or exceeds government minimum standards. Creating a system of culture among managers and employees that food safety is priority number one, will also help promote an effective food safety system, preventing a Chipotle-like outbreak.

Food Safety Magazine recommends these five steps for successful food safety training:

Conduct a training needs assessment

Perhaps everyone is aware of hand washing, but are shortsighted when it comes to food temperatures. Use regular training needs assessments to audit skills and evaluate employee competency.

Get employees involved in the process

Start a committee of employees to provide input for how the required training is implemented.

Test before and after

Assess the knowledge and skills of employees before the training and after to see how effective the training resources are.

Reinforce Standards

Reward employees who are safe when it comes to food handling and address any poor performances immediately.

Cross-train employees

Never have a vacancy that cannot be filled with someone who is trained to handle foods safely. Use cross-training to not only ensure food safety but develop employees for career growth and job satisfaction.

Topic(s):

Training

Related Posts

View All Posts

Standard Work

Best Practices of Food Manufacturing Hygiene Standards

32 min read

Food manufacturing companies have a responsibility to their customers to maintain high-quality control measures and hygiene standards. These practices are necessary to ensure...

Continue Reading

Training

Driving Fear Off The Factory Floor

15 min read

Did you know there are five fears that all human beings share? Below is the official list, according to the widely cited psychological research outlined in Karl Albrecht’s...

Continue Reading

Frontline Digital Transformation

4 Ways Digital Tools Improve Quality

9 min read

Twenty years ago, digital tools were “a thing.” Now they flow through all things. To some degree, every manufacturer is now a digital company. And with the right modern...

Continue Reading