Standard Work

7 min read

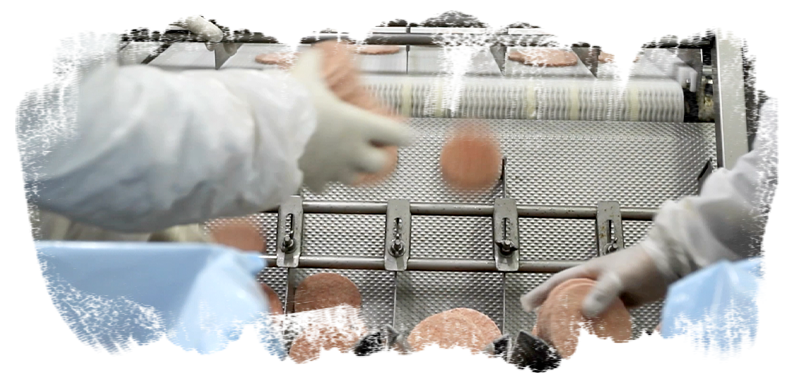

A Food Manufacturers Recipe for Quality

The status quo for food and beverage manufacturing has some new ingredients.

Consider several of the social, economic, and cultural trends impacting the industry:

- Consumers reshaped eating and drinking habits in the pandemic

- Food and beverage production has the highest employee turnover compared to other manufacturing sub-verticals

- Strict FDA restrictions mean paper documentation doesn’t work anymore

- Temporary, low skilled workforces need operational training that speaks their language

Plant managers have been pushed into unfamiliar digital territories.

So how will your facility ensure higher quality, reduced waste, and meet peak production demands?

Below, we will share stories from our food and beverage customers, insights gleaned, and tactics you can put into action immediately to build the frontline of the future.

But first, a short film to set the table:

Reduce Defects With A Universal Standard

Standards are a starting point, not the final destination. But if they only exist in people's heads, and they're not documented or agreed upon, then they’re about as useful as a bowl of cereal without any milk.

One of our customers, a food packaging business, shared a memorable story about product recalls. We talked to their learning and development manager, who reminisced about her (former) factory job. She said their frontline never used video SOPs before. But after digitizing their training, people on the team noticed a production anomaly after watching the video.

There was one step in their process that included wrapping a metal band around a piece of meat. And to their surprise, it appeared that a small shard of metal was flying off every time.

Nobody had noticed that previously, and it’s clearly an unacceptable result in food processing. Good catch!

Isn’t it incredible that something so small as a video has the ability to stop mass recalls in the future which could cost the company millions?

According to a recent McKinsey Manufacturing Report, 68% of defects are caused by human error. And all defects are a form of waste that food and beverage manufacturers must keep at a minimum. After all, defects need correction. Which means repair and rework, scrap, replacement production, and higher time, effort, and handling for inspections.

How is your facility creating a universal standard which employees actively engage with and trust?

In our experience, inefficient processing is often due to poor training, over reliance on tribal knowledge and outdated documentation. If you want to eliminate unnecessary motion, product defects and even recalls, consider using video SOPs. Create up to date, easy to follow work instructions so defects become a thing of the past.

Train For Troubleshooting

Another customer of ours is a food producer that specializes in taco shells. Tuesday is every day at their facility! Their line runs five hundred taco shells a minute. Unlike some manufacturers in their industry with diverse product lines, they make the exact same product. All day. Every day.

This operation is simple from a day to day basis. But when problems arise, it gets harder.

We observe many food manufacturers that don’t have a standard way to train operators on issues that might arise. Employees are solely focused on packing the item, running the machines and so on. They’re not necessarily trained to troubleshoot.

Our customer told their now legendary story about taco downtime on numerous occasions. See if it resonates with how your facility operates:

One evening, the overnight shift had a problem. The line went down for six hours. And nobody on the floor knew how to fix the problem, as they were all new hires. When the day shift finally came the next morning, within two minutes someone commented, “Oh, you just do this.” They flipped a switch and the problem was solved.

Six hours. Five hundred taco shells a minute. That’s close to two hundred thousand products not being produced in one shift. That delay takes quite an enormous bite out of the bottom line.

Are you training your frontline to solve problems, but also address the root cause?

Troubleshooting is about diagnosing in real time, in the heat of the moment. We suggest you adopt those ideas into your digital work instructions, and you'll save a lot of money. Even on a relatively simple, day one job, your operators should be thinking about troubleshooting. Newly hired frontline workers should be empowered with the ability to comment, observe, and improve. They immediately contribute to the standard.

The Recipe for Successful Transformation

Now that the status quo has changed in food and beverage manufacturing, it’s time to abandon outdated training and documentation practices. If you’re still using manual or paper based processes, then you might be biting off more than you can chew.

Remember to reduce defects within universal standards and to train for troubleshooting.

You’ll have the ingredients to build the frontline of the future.

Topic(s):

Standard Work

Related Posts

View All Posts

Continuous Improvement

Firefighting In Manufacturing

12 min read

Why It Happens, What It Costs, and How To Stop It Firefighting is a burning issue in manufacturing. Not only are facilities dealing with safety measures like flammable...

Continue Reading

Standard Work

How Auto Manufacturers Can Avoid Production Potholes

6 min read

Automotive manufacturing has been a windy road. Here are a few of the social, economic and cultural trends currently impacting automotive manufacturing. But automotive...

Continue Reading

Work Instructions

The Cost of Bad Work Instructions

10 min read

Bad work instructions are the norm. Documentation is often created to check a box for audit or compliance purposes. But once completed, those work instructions get trapped...

Continue Reading