Training

6 min read

Breaking Down the Skills Gap: Training

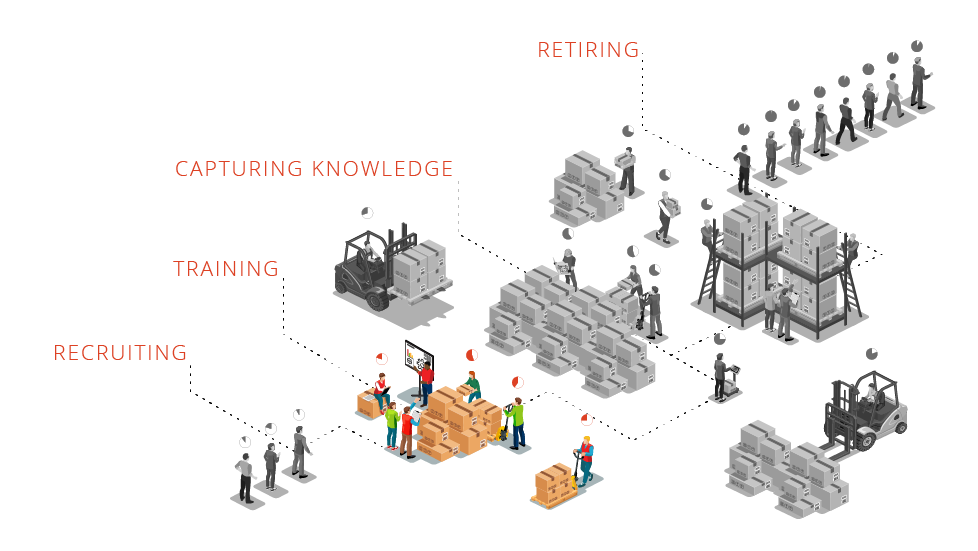

Manufacturing Institute estimated that 2.4 million job openings in manufacturing—accounting for half of all open positions—will go unfilled between 2018 and 2028 as a direct consequence of the skills gap.

This isn’t a future problem.

The challenges of the skills gap and a shifting workforce are impacting businesses right now.

The average U.S. manufacturer is losing an estimated 11% of its annual earnings (EBITDA), or $3,000 per existing employee, due to the talent shortage.

Time to take a fresh look at the skills gap.

Due to a shifting workforce and outdated training methods, many manufacturers are failing to capitalize on their workforce capacity within current talent pools. In fact, 84% of manufacturing executives agree that a talent shortage already exists in the U.S.

What can businesses do to bridge the skills gap and attract a skilled workforce?

The short answer — create better training programs.

Taking a hard look at your training program is necessary to adapt to a workforce in transition.

We know...this isn’t the silver bullet that the industry is looking for. However, traditional training methods are no longer capable of up-skilling employees effectively and are having a negative impact on quality, productivity, and employee retention. Taking a hard look at your training program is necessary to adapt to a workforce in transition.

The Cost of Poor (Non-Standardized) Training

More often than not, companies have formalized training programs, but in practice, skills are learned through a variety of informal ways. Ultimately, people rely on unofficial training methods like job shadowing, which have been common practice in many businesses for decades.

These traditional training methods are inherently non-standardized and an inefficient way to transfer knowledge. Not only are they wasteful, but they increase safety risks and negatively impact quality. In fact, 85% of quality costs are still caused by worker errors. This indicates that training programs still aren’t where they should be. While these traditional approaches have been sufficient for their time, they ultimately lack standardization and could be improved upon.

“Every large company has some type of training program in a large variety of areas….. Yet, go where the actual work is being done and ask people how they learned their jobs and you get a different picture."

- Liker and Meier 2007, Toyota Talent

One-on-One Training

Practices like job-shadowing and on-the-job (OTJ) training lack both scalability and visibility. These peer-to-peer coaching methods are only possible with enough experienced workers available to train others. As more experienced manufacturers reach retirement age, fewer mentors are available for this training method to be practical.

Even if mentors are readily available, these methods still lack standardization, and the quality of training can be highly variable. Without a standardized system to manage training and knowledge transfer, best practices are left up to the experience, training technique, and frankly, mood of each employee.

Instructor-Led/Classroom Training

Training in a classroom has the benefit of scalability, but significant downtime or productivity loss is often required. This makes classroom-based training inefficient from a production standpoint, and difficult to coordinate around multiple shifts.

Classroom methods can be necessary for certain types of training, however, comprehension and retention is at an all-time low in this type of learning environment. People learn best when they have strong visuals and can apply their knowledge in the proper context.

Manufacturing Training Has to Change

Rather than defaulting to these traditional training methods, manufacturers need to look towards new technology to supplement and formalize their strategies for training the incoming generations of workers.

Things are different now. Workers only stay with a company for 2-3 years, not 20-30. In fact, the average American worker stays at their job for 4.6 years; for millennials, reduce that to 3.2 years.

the average American worker stays at their job for 4.6 years; for millennials, reduce that to 3.2

3.2 years.

Let that sink in.

Where previous generations had entire careers to develop skills, the current workforce has approximately 10% of that.

3.2 years to hire and train someone. 3.2 years to cultivate their skills as a valuable contributor to your organization. 3.2 years for those same people to provide process insights and improvements. And 3.2 years to capture that before they walk out the door.

Fortunately, the shifting workforce comes with its own advantages as well. They are known as “digital natives.” This means they are well equipped to leverage new technologies to improve training strategies.

With these shorter periods of employment, manufacturers can no longer rely on traditional training methods to get new hires up to speed. Instead, innovative and standardized approaches need to be used in order to train new hires quickly and retain talent.

At Dozuki, we’ve built a system that enables you to train new hires faster and standardize best practices. For practical strategies to improve your training and bridge the skills gap, check out our free e-book.

Topic(s):

Training

Related Posts

View All Posts

Frontline Digital Transformation

Where is Your Implicit Knowledge Hiding?

5 min read

Implicit (tacit) knowledge is difficult to communicate and often remains isolated in the heads of employees. However, this accumulation of operational skills and insights has...

Continue Reading

Training

Document Management Vs. Knowledge Management

4 min read

Understanding the distinction between document management and knowledge management is vital to operational excellence. While the terms can sometimes be used interchangeably,...

Continue Reading

Training

Why HR Shouldn't Manage Your Technical Skills Training

6 min read

Amid the Silver Tsunami, HR departments are hustling to onboard and fill personnel gaps, but they can’t predict the evolving demands of your operations. Manufacturing...

Continue Reading