Industry News

19 min read

Impact of AI in Manufacturing: Benefits, Challenges & Use Cases

Artificial Intelligence has become a hot topic in society today. What once was a term relegated to science fiction novels is now commonplace among people from all walks of life.

Table of Contents

1. Benefits of AI in Manufacturing

2. Challenges of Implementing AI in Manufacturing

3. AI Use Cases in Manufacturing

4. Ethical & Regulatory Considerations

5. Collaboration of AI & Humans

As the uses and benefits of this cutting-edge technology become apparent, society is quickly becoming more comfortable using AI in applications of all kinds – from art and language to business and finance and beyond.

But an argument can be made that nowhere is AI more groundbreaking in its benefits than the manufacturing industry.

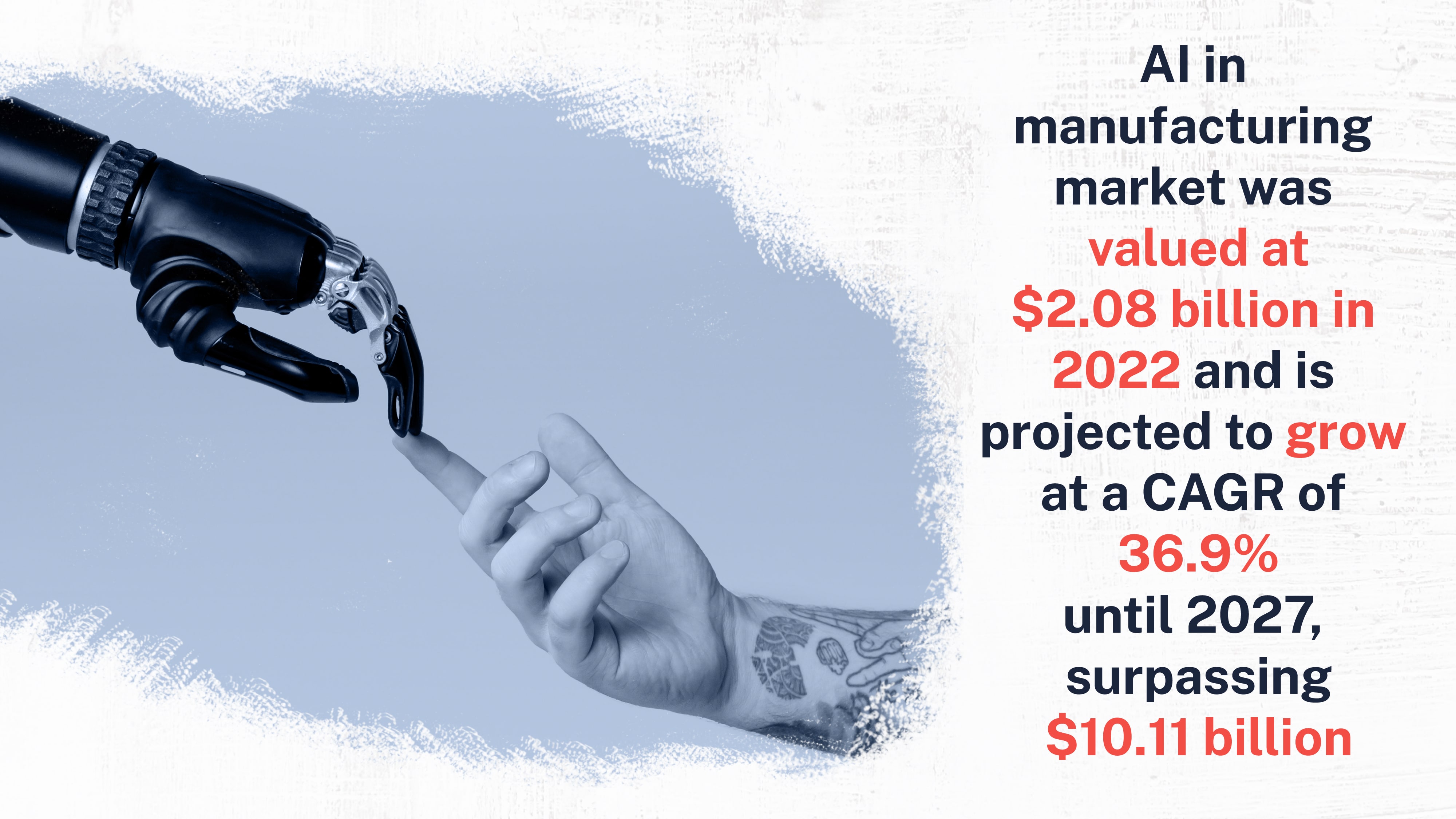

The global AI in manufacturing market reached a value of $2.08 billion in 2022 and is expected to see a compound annual growth rate (CAGR) of 36.9% through 2027, reaching a value upwards of $10.11 billion.

Implementing AI in manufacturing settings can help organizations in significant ways (think increasing productivity, reducing costs, boosting quality, and minimizing devastating downtime).

When organizations leverage AI technologies, such as automation, machine learning, and deep learning, they can analyze data more effectively.

What follows is the opportunity to make smarter, more informed decisions.

This article will dive into the impact of AI in manufacturing, including its benefits, the challenges that companies face when implementing any new technology, and potential use cases that could change how factories run.

Benefits of AI in Manufacturing

The benefits of AI in manufacturing are many, and it boils down to this: there are instances where computers simply do it better - faster, more accurately, and more effectively.

Implementing these technologies in the right places gives organizations an advantage, primarily because AI provides a better way for manufacturers to use data.

85% of company executives believe AI could provide a competitive advantage. And they’re not wrong.

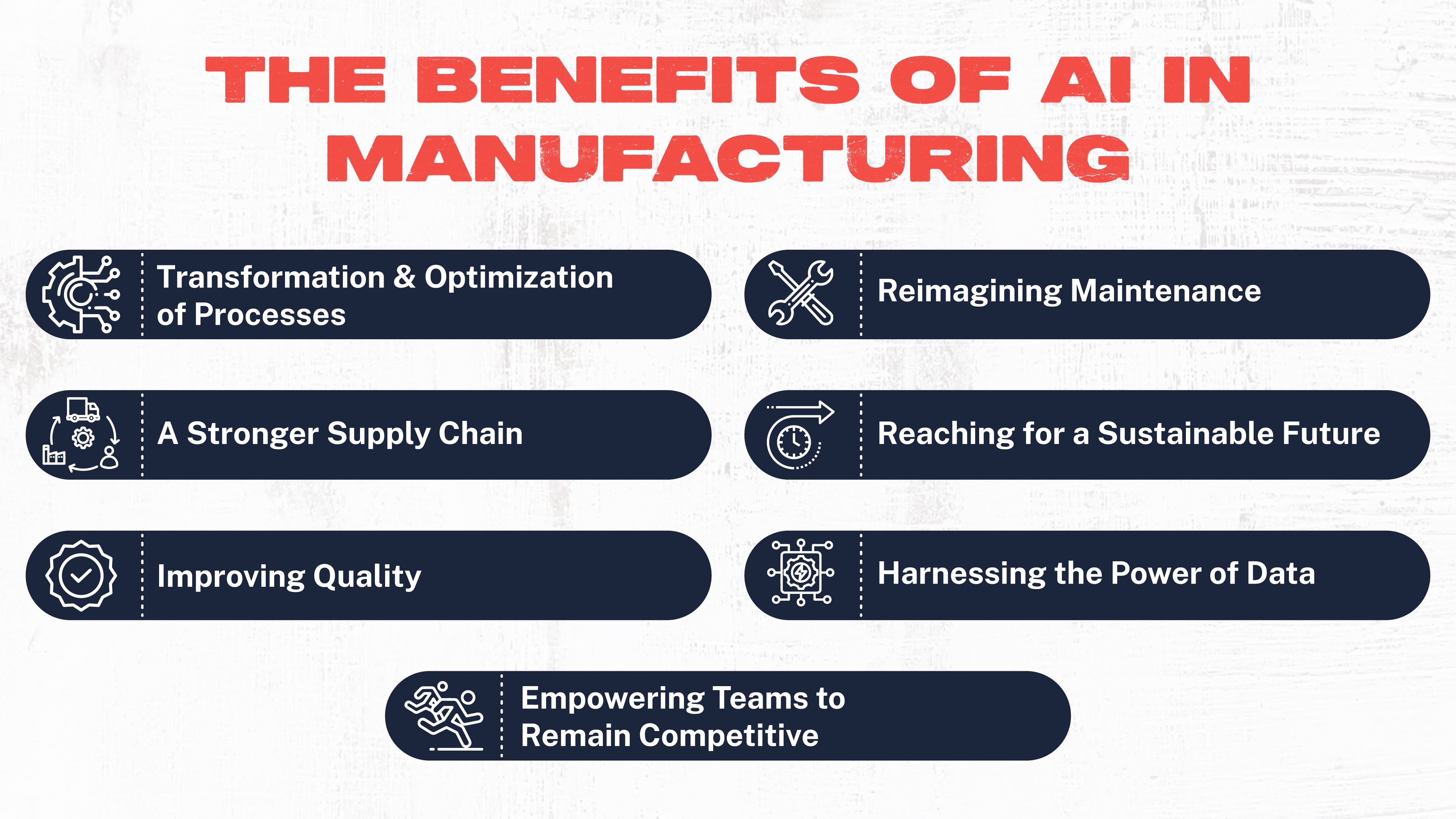

Below is a list of some of the most significant benefits manufacturing organizations gain when implementing effective AI transformations.

Transformation and Optimization of Processes

AI is a wide-reaching technology with numerous applications in the manufacturing industry. By implementing AI, organizations gain the ability to transform their processes, from design to maintenance, production, forecasting, customer relations, and beyond.

The result is an organization that can build a safer, greener, faster, and more high-performance environment by leveraging digital technologies.

A Stronger Supply Chain

With more accurate forecasting, organizations can strengthen their supply chain, which companies need more than ever in this post-Covid landscape.

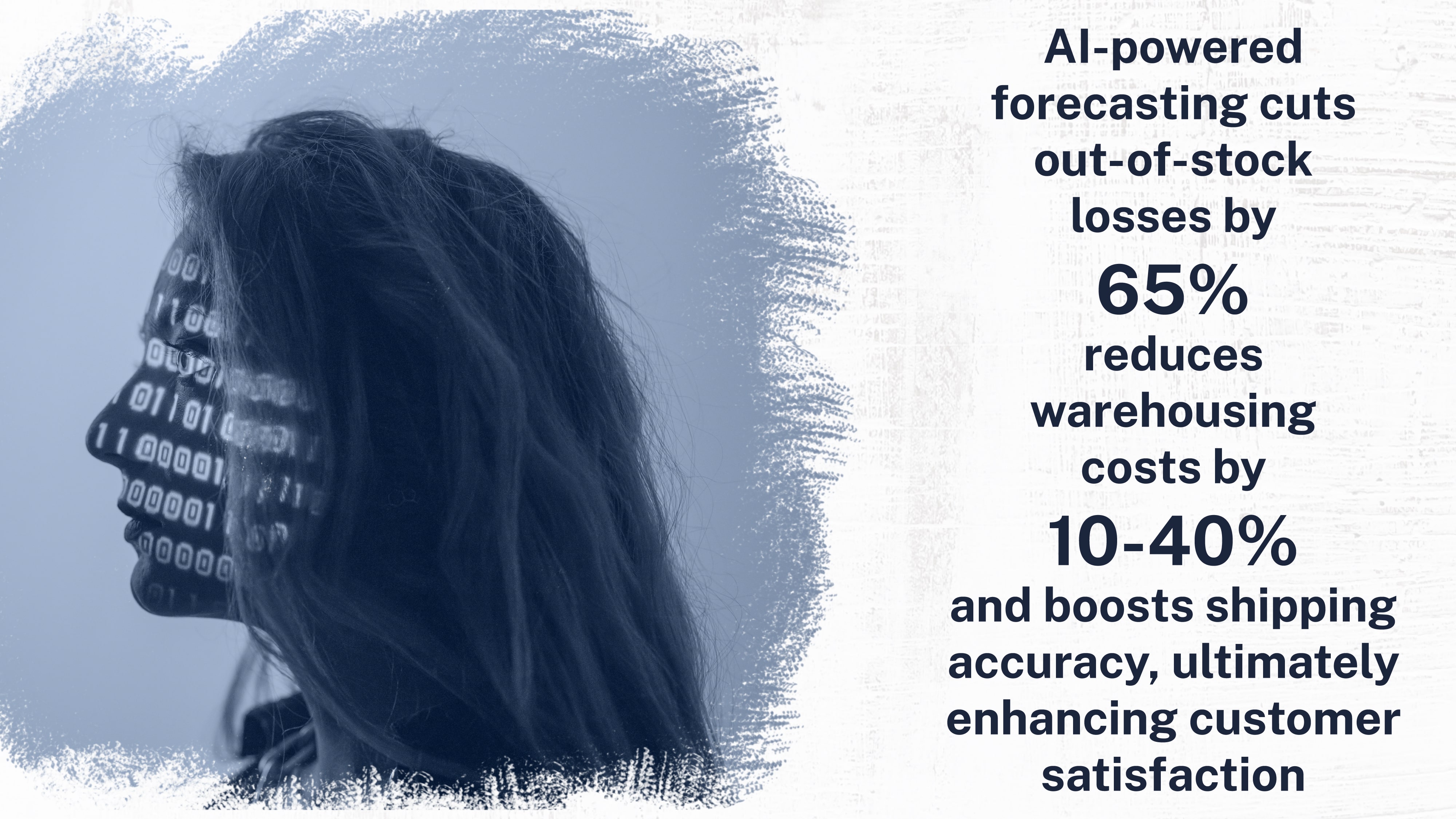

AI-powered forecasting can reduce lost sales related to out-of-stock by 65% and warehousing costs by 10-40%. And it can enable faster, more accurate shipping and delivery, which is bound to result in more satisfied customers.

Improving Quality

Quality is top-of-mind for most manufacturing executives. With AI technology leading the quality sector, manufacturers can increase their defect detection capabilities by a staggering 90%.

From a production standpoint, AI can provide better visibility and oversight end-to-end, boosting production by 20% and quality by 35%.

Reimagining Maintenance

Organizations implementing machine learning techniques to facilitate predictive maintenance programs can cut unplanned downtime and maintenance costs by as much as 30%.

With a more remarkable ability to detect production defects, organizations can ensure quality assurance, satisfy real-time demand changes, enable greater customization, and cut downtime costs.

Reaching for a Sustainable Future

Reworking a maintenance program from preventive to predictive not only reduces downtime but can provide overall savings of between 8%-12%, according to the U.S. Department of Energy.

These savings come in the form of reduced operational costs. They are beneficial for the environment as well because they extend the lifetime of machinery, reduce CO2 emissions, help conserve energy, and even result in a workforce that performs at a higher level.

Harnessing the Power of Data

At the heart of AI is data and being able to analyze and apply that data more efficiently and effectively. The manufacturing industry collects more data than virtually any other, but much of that data goes to waste.

By reprocessing received data and harnessing its power, manufacturers can generate new ideas, reduce the probability of errors, and build more optimized production programs.

Ultimately, AI helps manufacturers boost overall efficiency corner-to-corner, including areas like quality, safety, production, and even managerial tasks.

Empowering Teams to Remain Competitive

Today’s manufacturing organizations are in the process of rebuilding, rethinking, and restructuring the future of the industry. The smart factory has become standard, and AI is leading the way down this new road.

By allowing increased efficiency, quality excellence, the downsizing of time and costs, and overall optimization of production and processes, AI gives organizations a better chance to remain competitive in this transformative time.

Challenges of Implementing AI in Manufacturing

Implementing any new technology is a tricky task, but the size and scale of the manufacturing industry make it even more challenging. The goal, of course, is to end up in a better place. However, getting there smoothly and with as little disruption is critical.

Manufacturers must maintain production levels and customer satisfaction throughout the process. And they must provide employees and workers with the proper training and motivation to ensure everyone is on the same page. Easier said than done.

On top of the challenges of implementation are the inherent struggles that come with AI in manufacturing. Accurate, real-time data is a cornerstone of the process; without that vital component, the rest of the system falls apart.

Below are some of the most common challenges organizations face when implementing AI and some tips on overcoming them.

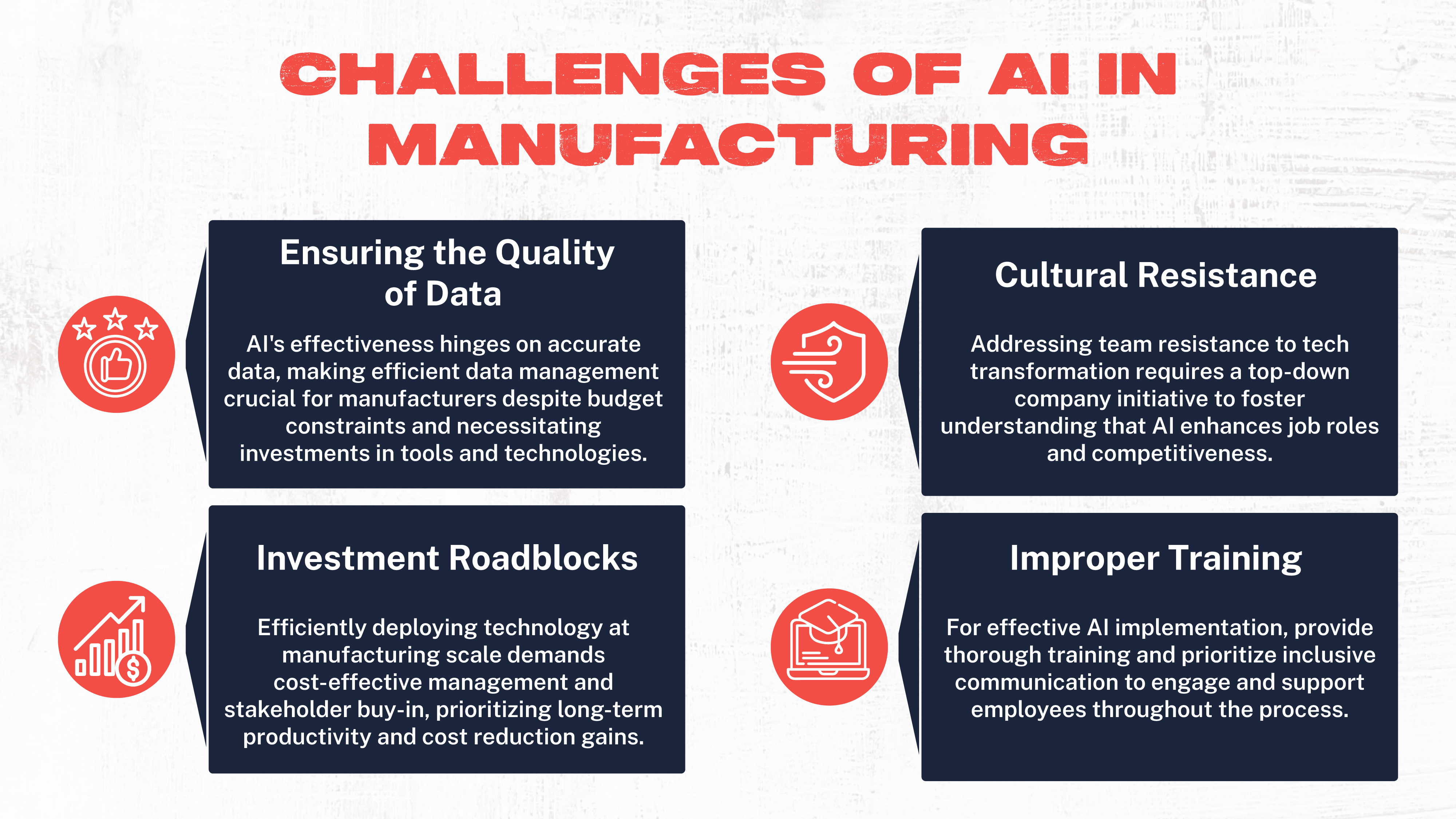

Ensuring the Quality of Data

AI uses models and algorithms to get jobs done. No matter the application, the crux of these models is data.

AI relies on accurate, high-quality data for making reliable predictions and decisions. If the data is accurate and collection takes less time, then the data becomes flawed, and the outcomes will be more of a hindrance than a benefit.

The answer for manufacturers is to build an efficient data management system.

This often requires an investment in data collection tools and technologies and the procedures required to overcome this obstacle, which brings us to our next challenge: the budget.

Investment Roadblocks

Technology is expensive, especially considering the scale required for most manufacturing businesses.

While this is no surprise to most organizations, budgeting for a full-scale transformation can be daunting, and getting investors and stakeholders on board is essential.

The best advice here is to implement technologies in the places where they will make the most difference. And focus on the long-term benefits of things like productivity and cost reduction. As they say, it pays to play, but one must first shoulder the investment burden.

Cultural Resistance

While the investment dollars needed to begin a tech transformation might not come as a shock, the one thing that often does is resistance from team members.

Manufacturers rely on people to get the work done, which won’t change even after the implementation of AI. What’s important is to help everyone understand that fact.

Organizations need to create a company-wide initiative that starts from the very top and includes workers in the conversation.

If employees understand that AI won’t replace them but instead make their jobs easier and guarantee that their company can remain competitive long-term, they will be more accepting of change.

Improper Training

Lastly, implementing AI technologies requires proper training. Workers must be provided with the tools they need to succeed in any job role, including in-depth training in new systems and technologies. A focus on communication is also essential.

Employees need to feel like they’re a part of the process instead of just at the mercy of this new tech. Facilitate conversations between employees, managers, and supervisors.

Keep communication lines open throughout the process so employees feel comfortable asking questions and raising concerns when they arise.

AI Use Cases in Manufacturing

We’ve listed the benefits organizations can gain from implementing AI in manufacturing. Manufacturers can achieve end-to-end visibility into all operations by embracing AI technology head-on.

When done correctly, the result should be lower costs, improved efficiency, optimal AI-enabled generative designs, and a more robust supply chain.

There are numerous uses for AI in the manufacturing industry. We’ve touched on a few, but below are the three we consider the most transformative and the most important for organizations seeking to harness the power of AI in their operations.

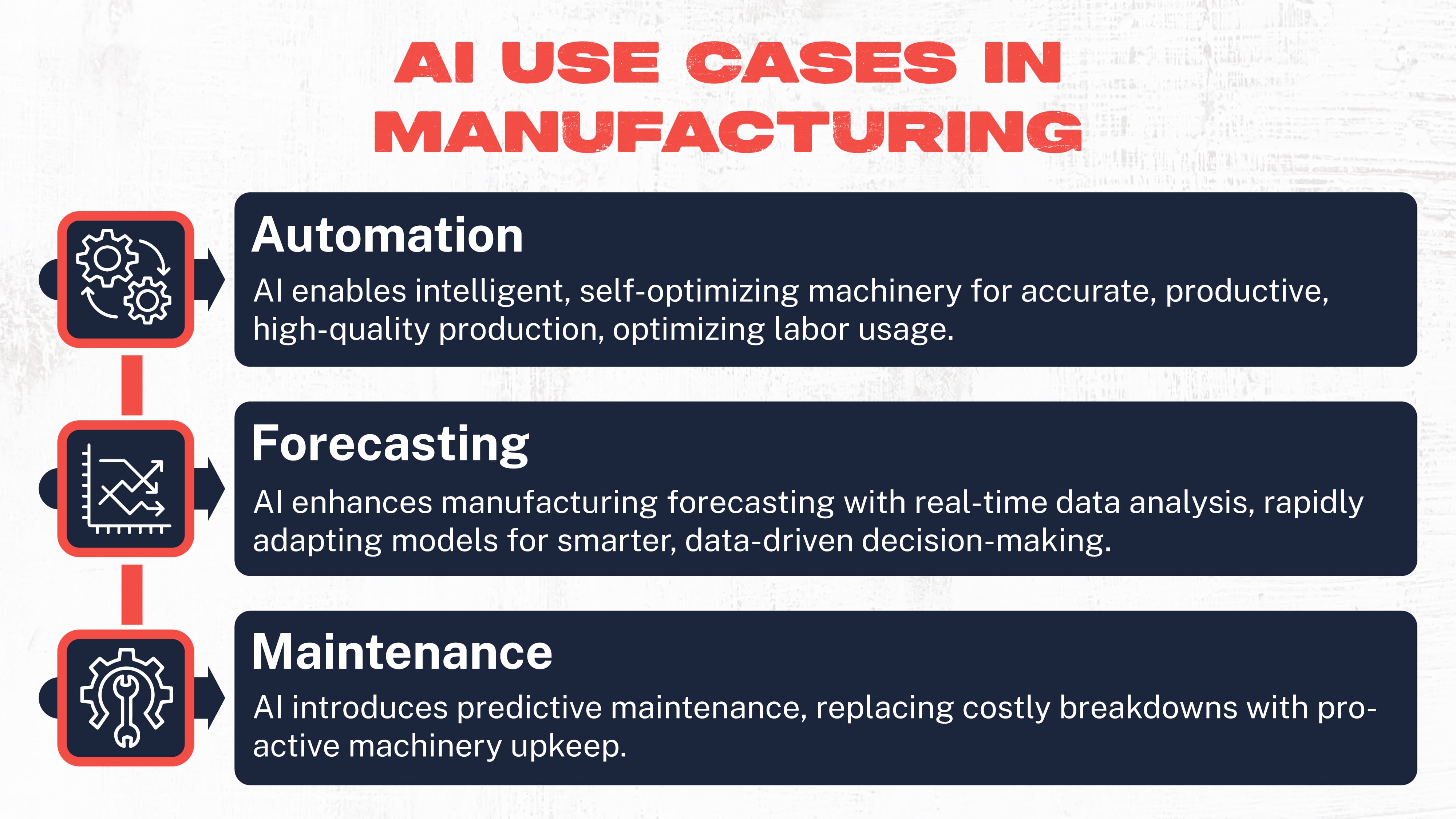

Automation

AI allows for the use of intelligent, self-optimizing machinery. These "smart" machines can automate the production process, resulting in more accurate results, increased productivity, and a greater ability to turn out high-quality products.

Automating time-eating processes allows organizations to utilize their labor force better and boost productivity.

Forecasting

One of the most beneficial uses of AI in manufacturing comes from more efficient and accurate forecasting. AI can create models that predict future outcomes by collecting and analyzing real-time data.

Forecasting is not a new practice in manufacturing. But with AI at the helm, companies can get better results and faster.

AI models can draw in data instantaneously and adapt to quickly changing scenarios. AI use in forecasting allows for better planning and more intelligent, information-driven decision-making.

Maintenance

Manufacturing companies spend millions on maintenance programs every year. Without maintenance, machinery breaks down faster, and production stops until repairs can be made.

Until recently, preventative maintenance was the go-to practice for manufacturers. However, with AI technology, organizations can implement predictive maintenance programs.

With predictive maintenance, organizations can see into the future and understand exactly when a piece of equipment will likely fail.

This allows for better planning of repair and maintenance activities, reduced costs and downtime, and better decision-making regarding production planning.

AI helps manufacturers detect quality defects faster and more efficiently so that maintenance and quality can work together.

Ethical & Regulatory Considerations

Manufacturing organizations are no strangers to regulatory considerations. Every activity within the manufacturing industry has an impact – on employees, on the consumer, and on the environment.

With these things in mind, manufacturers strive to put it all together in a profitable and still ethically and morally responsible way. If they don’t, they face steep fines and penalties from regulatory bodies and even steeper judgment from workers and consumers.

What does all this mean regarding the transformation of the industry to include AI in manufacturing?

It means nothing has changed – and everything has changed. Organizations are still responsible to society, consumers, and their employees.

Only now, additional considerations on the table revolve around the implementation and use of AI technologies in everyday operations.

Organizations need to take ownership of the outcomes generated by AI, both positive and negative. The organization is responsible for understanding and communicating transformation's potential intended and unintended consequences.

And they need to ensure that decisions made throughout the process align with ethical standards and maintain transparency for all involved.

Responsibility to Workers

No business can disregard their responsibility to their employees. The law often forbids it (think areas like safety and labor practices).

In other ways, companies must consider their employees and their work environment if they hope to keep those employees long-term.

Implementing AI within a manufacturing organization must be done with the workers in mind. Companies must carefully consider these drastic changes' impact on the workforce.

There’s a great deal of fear around using advanced technologies in industry, not just manufacturing.

As AI becomes more commonplace, much of that fear is abating, but it certainly hasn’t disappeared. Workers may worry that computers will replace them and eliminate jobs, and therefore, be resistant to change.

This makes it essential that organizations harness the power of AI not to replace human workers but to enhance their productivity and decision-making capabilities.

Employees deserve job security and must not be made to feel like they will show up to work one day to discover their role has been eliminated because of AI technology.

Balancing the benefits of AI with the ethical responsibilities that manufacturers have to their employees is vital for the business's success and the workforce's well-being.

Responsibility to Consumers

At the end of the manufacturing process chain is the consumer. With the participation and loyalty of that consumer, manufacturers will be able to remain afloat.

Consumers demand high-quality, safe products resulting from sustainable and ethical production processes.

AI provides many benefits for manufacturing organizations. However, companies must remember that they are responsible to the consumer.

Harnessing the power of AI for an increase in productivity and profitability must be carefully balanced with ongoing evaluation and transparency.

Responsibility to the Organization

With any initiative, it can be tempting for upper-level executives to get wrapped up in outcomes.

When executives who are not at ground zero of implementing a complete overhaul of processes and practices start spouting that "corporate-speak," peppered with superlatives and promises, it can alienate the employees doing the actual work and the investors footing the bill.

Executives should avoid over-promising outcomes when it comes to the implementation of AI. Instead, there needs to be a systematic approach that focuses on incremental results in specific processes.

Yes, there is incredible value to the use of AI in manufacturing. However, companies should communicate the cost from all perspectives to help everyone understand the realistic value of transformative changes.

Collaboration of AI & Humans

When discussing the implementation of AI in manufacturing, most of the focus is on what these types of technologies can provide for the organization.

The typical conversation starters are increased productivity, reduced costs, greater efficiency, and quality. Most of these benefits evolve from taking advantage of AI from a production and decision-making standpoint.

Looking at this way can make it feel like organizations are implementing AI over other, less-productive processes. And in many ways, that’s true. But what’s missing from the conversation is this.

Instead of viewing AI as a replacement for processes, it should be viewed as a tool that combines the efforts of humans and computers, not one that undermines the role of humans in the industry.

Collaboration – Not Competition

When organizations implement AI with collaboration in mind, it unlocks extraordinary opportunities for innovation. Business activities and decision-making rely on things like creativity, intuition, and intelligence, driven by the people behind the scenes.

That fact doesn’t change with the implementation of technology. When collaboration remains paramount, companies can achieve remarkable breakthroughs and achievements due to the combined strengths of both humans and AI.

This outlook is essential for the ongoing success of the industry as a whole and focuses on the benefits computers and humans can offer each other instead of how one might replace the other.

Leveraging AI, the Right Way

By focusing on collaboration and using AI as a tool capable of enhancing inherent human capabilities, organizations can gain the most benefit.

AI can help humans make better decisions, improve problem-solving strategies and outcomes, and provide valuable insights during creative tasks.

There’s a synergy that must be developed between human intelligence and the computational abilities of AI technology.

Finding that synergy and harnessing it enables a more effective analysis of the vast amounts of data that manufacturing creates and leads to more innovative solutions and ideas.

The manufacturing industry needs to take a new perspective on using AI and advanced technologies. Humans and AI need to work together to achieve shared goals. When that happens, it enhances innovation instead of hampering it.

Final Thoughts

Manufacturing is one of the most dynamic and fast-changing industries in history. It’s always been that way since Henry Ford first envisioned an automobile rolling off an assembly line. With advanced technologies and AI leading the way, the speed of that innovation and transformation is accelerating beyond belief.

Because of this rapid transformation, implementing AI in manufacturing might seem an overwhelming and daunting for organizations. But the fact remains that AI has the potential to revolutionize the manufacturing industry, and that revolution is already in progress.

By leveraging AI technologies, organizations can improve their operations from end to end. Machine learning, deep learning, automation, and other uses can help companies analyze valuable data more effectively, make better-informed decisions, and gain a competitive edge that is beneficial in today's landscape and essential.

Instead of fearing the future and holding firm to outdated outlooks related to computers replacing humans, organizations must focus on building a mutually beneficial relationship between industry and AI. There’s is much to learn and many innovations on the horizon.

It’s time for the industry to harness the power of computers for the benefit of everyone and figure out how to do it in a way that enhances the innovation and creativity that has helped build the manufacturing industry into what it is today.

Topic(s):

Industry News

Related Posts

View All Posts

Continuous Improvement

Maximizing Efficiency: A Guide to Total Productive Maintenance

26 min read

Maintenance is an essential requirement for any manufacturing company. Whenever machinery and equipment enter an equation, there will be a likelihood of that machinery...

Continue Reading

Frontline Digital Transformation

A Comprehensive Guide to Predictive Maintenance in Manufacturing | 2023

18 min read

Effective maintenance requires a well-rounded approach. Manufacturing companies use planned, reactive, and proactive systems to prevent breakdowns and address problems as...

Continue Reading

Product

The Role of Industrial AI in Digital Transformation

6 min read

CreatorPro AI: A Holistic Approach to Digital Transformation Manufacturing organizations face a two-fold challenge when advancing digital transformation efforts: legacy...

Continue Reading