Continuous Improvement

3 min read

Implementing Continuous Improvement with Dozuki

Is your company interested in reaping the benefits of continuous improvement (transparency, efficiency, cost reductions, etc.) but aren't sure where to begin? Dozuki has you covered.

In this article we will highlight how our software can help. With Dozuki you can create, share, and improve the processes that keep your company moving forward, providing a real-time view of training and production metrics. Easier to setup than a full ERP system, and more manageable than excel or word documents, Dozuki is a better way to build a continuous improvement culture.

Outdated Tools

Standardization is the foundation for improving. For years, companies have relied on outdated software like Powerpoint or Word to standardize their processes. The result: confusing, insecure, and hard to update documentation.

78%

of manufacturers use outdated work instructions

Dozuki is a Lean Tool for Efficient Companies

Dozuki is a powerful software tool, designed with responsive features for your company’s needs. Collect essential data in real-time with data capture. Create and distribute documents from anywhere with centralized management. Leverage insights from your most experienced employees with built-in feedback tools.

Dozuki is a Lean tool, built to eliminate waste and make your company more efficient.

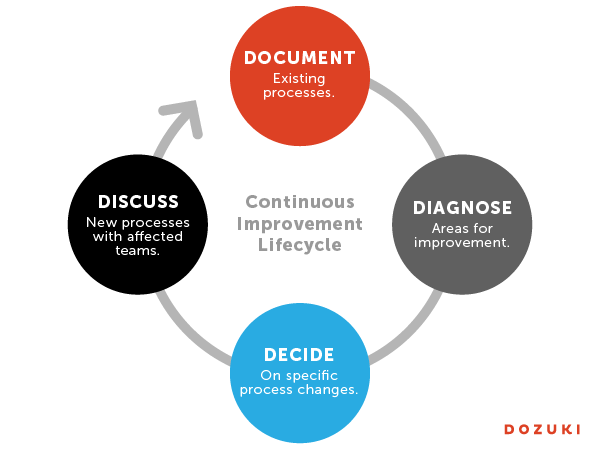

1. Document Processes

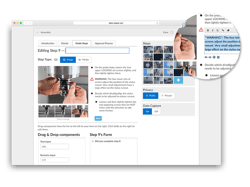

1. Document Processes

Use time observations to objectively record all repeated procedures. Maintain a standard format and supplement text with visuals.

Authoring in Dozuki uses templates with an emphasis on clear visual instructions.

2. Train to Standards

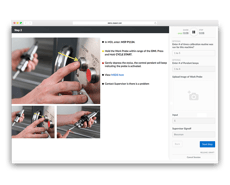

2. Train to Standards

Release the standardized procedures to essential employees and track progress.

Dozuki can display instructions one step at a time, tracking efficiency and gathering essential data.

3. Analyze Feedback

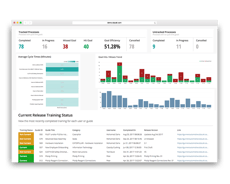

3. Analyze Feedback

Collect data directly from your procedures for analysis. Use these insights to improve processes and eliminate waste.

Customizable dashboards in Dozuki collect data and feedback automatically, allowing you to easily identify areas for improvement.

4. Communicate Changes

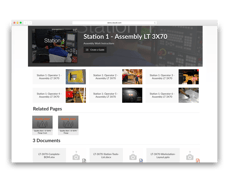

4. Communicate Changes

Gather the necessary approvals and release new versions to the relevant personnel; making sure to archive outdated procedures.

Dozuki automates this entire process, including release notes to help explain changes.

Endless Benefits with Dozuki:

-Streamline Workflows

-Reduce Waste

-Prevent Rework

-Control Processes

-Increase Engagement

-Train Smarter

Related Posts

View All Posts

Industry News

How Smart Factories are Impacting Productivity

5 min read

Deloitte research suggests that "smart factory" initiatives have yielded an average of 10-12% increase in labor productivity gains. Despite this success, a majority of...

Continue Reading

Frontline Digital Transformation

Top Challenges Impacting the Frontline Workforce

5 min read

Even with advancements in technology and automation, the frontline workforce remains essential to modern manufacturing operations. In fact, 72% of factory work is still...

Continue Reading

Frontline Digital Transformation

OSHA's Recommended Strategies for Improving Safety Programs

5 min read

Workforce safety is non-negotiable for any industrial business. When mistakes can cause serious harm or bring operations to a halt, companies can’t afford to take safety...

Continue Reading