Standard Work

5 min read

Inside the Mind of an ISO Auditor

Getting inside the mind of an ISO 9001 auditor is crucial to a successful ISO audit. Think of it like a gift — even the best of presents can be unappealing when wrapped in crumpled messy newspaper and duct tape.

Understanding the background and motivating factors for ISO auditors will help you portray the excellence of your operation in the best light possible. This article can help.

Where Do Auditors Come From?

ISO Creates Standards But Doesn’t Enforce Them

The International Organization for Standardization (ISO) develops popular standards such as ISO 9001, but they do not provide certification of those standards to companies; this is where third-party auditors come in. These third-party auditors are accredited bodies that perform audits and issue certifications to companies.

Who Certifies the Auditors?

Accreditation of the certification bodies falls to yet another independent organization, typically unique to each country, that verifies the competence of the certification bodies with the international standards. Accreditation is a formal recognition that a certification body is operating to international standards. While not required to become a certification body, it’s safe to assume that most “credible” certification bodies will have accreditation.

Say What You Do, Do What You Say

At the end of the day, an ISO quality audit consists of a third party evaluating the accuracy and effectiveness of an organization’s processes. They compare the outputs of said process to the planned arrangements and analyze how well they match.

In other words, are you doing what you’re saying you’re doing?

The Mind of an ISO Auditor

ISO auditors can’t look at everything. As a result, they’ve been trained to look for key indicators that reflect the overarching quality standards for an entire organization. Optimizing for these indicators will ensure that your ISO audit goes smoothly and that you’ve presented the best version of your quality management system. Below are the most impactful indicators that auditors are reviewing.

1. Dissemination of Organizational Knowledge

At this stage, most companies are documenting processes in some shape or form. Where many companies fall short is in their methods for accessing and distributing the information. Auditors want to see that finding and using information is easy.

Show This By:

Using a document management system that makes accessing information simple and intuitive. Auditors will interview a range of employees, and you don’t want to have to worry about training your entire workforce on how to access important information.

2. Hold Yourself Accountable

Auditors want to know that you’ve written quality policies and that you have some way to hold yourself accountable in the future. That said, having policies in place and using them are two completely distinct acts.

Show This By:

In addition to SOPs and operational procedures, document your standard process for internal audits and quality checks. Show that teams are following these procedures by logging their activity and verifying data by requiring signoffs by supervisors.

3. Roles and Responsibilities

Understanding how individuals fit into the overall goals of quality policies is key to understanding their importance. The primary motivation for connecting quality standards to employee responsibilities is to align an organization’s Quality Management System (QMS) with individual ownership of improvement.

Show This By:

Using a QMS software that connects approved procedures to the proper teams and personnel. Employees should be familiar enough with these procedures to articulate them in their own words and how their role contributes to company policy goals.

4. Engage in Process Improvement

Another element of employees interacting with documented processes is their ability to engage with the processes for corrective actions and process improvement. Auditors want to see that employees have the ability and will to provide feedback and implement improvements.

Show This By:

Establish a standard practice for providing feedback, be sure to share this with all employees to improve engagement. More importantly, this feedback mechanism should take place where the work happens (gemba).

Same Standards, New Challenges

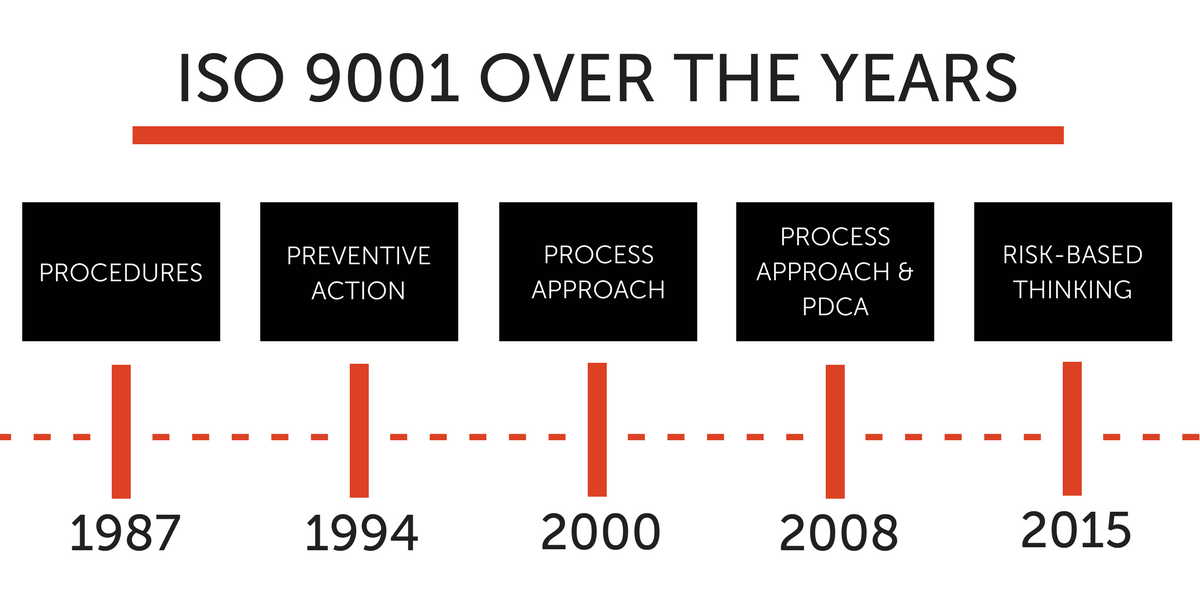

The new ISO 9001:2015 standards will be required by September of 2018 in order to stay current with ISO 9001 certification. The underlying goals of the standards haven’t changed, but ISO has made some key changes to adapt standards to the global market. The new standards place a heavy emphasis on process improvement and risk-based thinking.

Make sure you’re prepared to update your certification and have a thorough understanding of the key difference in the new standards.

Sources:

- 9001 Academy: "What does ISO 9001 Lead Auditor Training Look Like?"

- Quality Digest: “ISO Audit: Five Not-So-Easy Questions"

- International Organization for Standardization: “The Facts about Certification”

Related Posts

View All Posts

Work Instructions

How to Get ISO 9001 Certified with Dozuki

6 min read

As the most commonly used standard for quality management systems (QMS), the ISO 9001:2015 standard implements a preventative, risk-based approach that puts documentation at...

Continue Reading

Training

What to Look for in QMS Software

5 min read

Traditional quality management system (QMS) software does exactly what it’s supposed to do. Like file cabinets for the digital world, they organize and control your company...

Continue Reading

Continuous Improvement

What is Standard Work?

6 min read

Lean operations and manufacturers have used Standard Work for decades, yet many companies lack clarity when it comes to this fundamental lean methodology. How is Standard...

Continue Reading