Success Stories

5 min read

Patagonia's Journey to Train Their Customers

For years, Patagonia has set a high standard for product lifespan with their Ironclad Guarantee and unparalleled customer service. They’ve been providing free repair services for garments that have been ripped, torn, or otherwise damaged since 1973.

Their repair department—based in Reno, Nevada—is the largest garment repair facility in the United States, with a humble team of just 45 people. Even with such a small team, they are able to receive, repair, and return garments within 30 days. An impressive turnaround time if you’ve seen the state that some of these clothes arrive in.

As Patagonia has exploded in popularity, their repair services have had difficulty meeting the increased demand. In 2010, they repaired roughly 12,000 items, today the annual number of garments repaired is over 30,000—a 150% increase.

So how does a large outdoor apparel company mitigate this increasing demand?

Simple. Bring repair to the customers.

How to Empower Your Customers

Patagonia has been taking an active stance against over consumption since their humble beginnings, advocating for product longevity over purchasing new apparel every season. In 2011, they famously stood by this philosophy in an iconic Black Friday ad, which bluntly stated, “Don’t Buy This Jacket.”

In addition to bringing this ethos into their advertising, they also created the Worn Wear program, designed to save garments from landfills. The Worn Wear truck travels the country, fixing torn jackets and backpacks from state to state. Their motto — “If it’s broke, fix it!”

Dozuki's Contribution

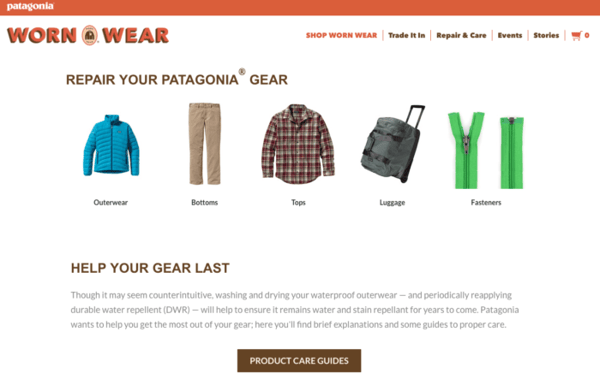

From fixing broken zippers to a simple patch-job, the partnership was able to create useful repair instructions for customers of all experience levels. Using the Dozuki platform, they shared these guides on the Worn Wear site.

Dozuki’s integrated collaboration features also helped turn this online guide collection into vibrant online community.

As a customer, all you have to do is locate the style number on your Patagonia gear and match it to the corresponding repair guide. From there, Patagonia’s repair department will ship out the fabric and replacement materials needed for repair. Once they arrive, follow the corresponding guide online, and voila, your item is fixed.

An Added Benefit From Documenting Procedures

With high-quality repair information readily available to the general public, Patagonia was surprised to find that the repair guides also improved employee training efforts.

We weren’t.

We spoke with Nellie Cohen, Program Manager for the Patagonia Worn Wear program, to gain some insight on how guides on Dozuki improved internal training.

"In our stores, we would always hear "Oh, the guy who used to do repair left," or "we don't have the right parts," there was always an excuse."

Cohen was privy to an insight that we are all too familiar with here at Dozuki — company knowledge isn’t a group asset unless it’s properly documented and standardized. The Worn Wear program found that by standardizing one process (product repair), they were able to standardize related processes as well.

"The repair knowledge in our stores was mostly passed down and wasn't institutionalized. But now, with training online, it helped us streamline the repair process. This increased employee accountability and ultimately helped create a better customer experience."

Instead of repair skills being passed down through more experienced employees, the information is now accessible to everyone. Employees and customers at stores across the world can perform repairs at Patagonia stores, rather than shipping them to the small Reno facility.

Key Takeaways From Patagonia's Training Program

- Empowering your customers can have a tangible ROI and build brand loyalty.

- Keeping knowledge inside the heads of a select few is neither helpful or scalable.

- Documenting important skills and procedures is what turns individual knowledge into a group asset.

- Making training information easily accessible increases employee accountability by eliminating excuses.

Training Procedures: If They’re Broke, Fix Them

The most important takeaway from Patagonia’s journey is to understand that even the most noble of causes have their share of logistical challenges. Standardizing common procedures is an essential component in creating training materials that are both effective and can be distributed easily.

Related Posts

View All Posts

Success Stories

How Dozuki Streamlines Knowledge Transfer

4 min read

Dozuki is changing how companies operate by eliminating unnecessary steps from critical workflows. This article explores how to drive efficiency and highlights a real-world...

Continue Reading

Product

How to Use Dozuki for Work Instructions

7 min read

Dozuki is the leading digital work instruction tool for industrial businesses all over the world. Our platform enables better employee performance by improving how you...

Continue Reading

Success Stories

How Dozuki Streamlines Authoring Time

6 min read

Traditional methods of updating and distributing process documentation can be incredibly time consuming. For one Fortune 100 heavy machinery manufacturer, the manual process...

Continue Reading