Continuous Improvement

7 min read

Upgrading Processes with Continuous Improvement

Many companies implement formal versions of Lean or Agile methods, but others have grown with the flexibility that continuous improvement provides, giving them the freedom to deviate from the formal approaches of Lean/Agile methods when needed.

Regardless of size, companies can struggle with keeping employees motivated in working towards shared goals. Engaged employees are your front-line in solving problems, and delivering value for customers—all activities which impact the bottom line.

Continuous improvement, or Kaizen, is a method for creating a culture where teams are invested on company goals and streamlining processes. And we can help you get started.

Continuous Improvement: Flexibility When You Need It

Continuous improvement provides the flexibility to create guidelines for eliminating waste and non-value add activities. Above all, this Lean methodology promotes a problem-solving culture which respects its people.

Maneesh Bhatnagar, Director of Quality & Continuous Improvement at the Dover Corporation, shared a few best practices he's gleaned from his his twenty-plus years of experience implementing continuous improvement and quality management programs around the world.

"A focus on problem-solving ensures employees are always finding ways to improve."

“Continuous improvement is not the equivalent of having an expert to solve all problems,” states Bhatnagar, “instead, it aims to foster an environment where every single person becomes a problem solver.”

This work environment with a focus on problem-solving ensures employees are always finding ways to improve, and ultimately delivering more value to customers, and the company.

Endless Benefits

From higher employee engagement to reduced errors, continuous improvement provides numerous opportunities for companies of all types.

Streamline Workflows

Reducing operational overhead is directly tied to creating more efficient workflows. By streamlining existing workflows, companies save time and money, and ultimately deliver more value to customers. For example, projects that involve multiple departments, changes in scope, and additional challenges offer opportunities to identify improvements.

Reduce Waste and Prevent Rework

Project costs can be best understood by knowing the amount of time it takes to get work done and the amount of variation (waste) to expect. Companies can reduce these costs by duplicating the best known practices across teams, creating higher levels of consistency, reducing waste, and preventing rework from consuming valuable resources. Not only do continuous improvement principles help maintain uptime, it also helps with project forecasting efforts.

Galvanize Employees

Engaged employees are the front-line in identifying opportunities for improvement. A culture of “not my problem” only creates quality issues, disconnected employees, and shrinking profits.

When members of the company understand they have a shared goal of improving and streamlining operations, they also become more effective. As processes are improved, employees receive consistent training, and the principles of continuous improvement thrive.

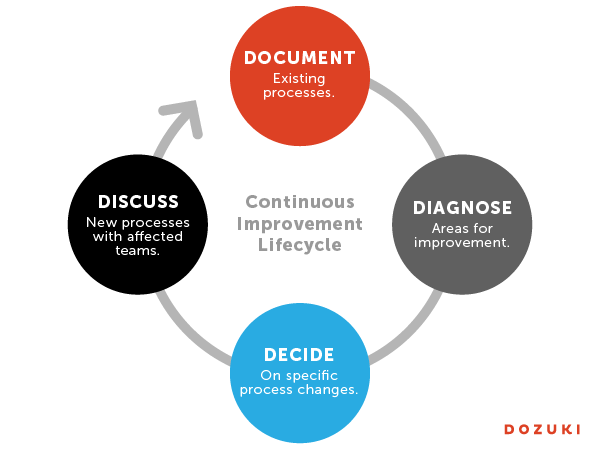

Getting Started with Continuous Improvement

Document Existing Processes

Often companies will have a wealth of processes and information locked in tribal knowledge. This presents a major risk. When employees ‘just know’ how to do something, that knowledge is not transferrable and not able to be improved.

Bhatnagar suggests taking the time to establish basic documentation of primary tasks, “An important part of continuous improvement is realizing that without a standard, there is no benchmark to improve upon.” Documenting existing processes and standards is essential in setting teams up for success with continuous improvement. Teams should break down each process step as much as possible, clearly identifying the actions involved.

"Without a standard, there is no benchmark to improve upon."

These details are often the easiest places to start when kicking off continuous improvement initiatives, as they spark the problem-solving culture companies seek to create. “We want to have a culture that encourages people to suggest changes if it’s going to make the process better,” states Bhatnagar, “and then, we train everyone who works on it so we are all doing it the same way.”

Gather Feedback From Employees

Involving employees who aren’t familiar with the process may seem counterintuitive, but can be helpful in providing fresh perspectives to identify obvious opportunities for improvement. Scrutiny is essential during this stage, as even the smallest suggestions can yield positive results.

Questions to ask when evaluating areas for improvement:

- Do we have a documented standard for the current process?

- How much time is spent working on the current process?

- Who is affected by this process?

- What do we gain if we spend time improving this current process?

- Are there other processes we need to examine first?

Communicate With Impacted Teams

Once teams have decided on a new process, it’s time to share with all impacted employees. If new a process impacts another established process, take the time to work with that team to make necessary modifications to accommodate the improvements.

“Consistency is paramount, otherwise the improvements get lost in translation."

Sharing improved processes can be one of the most challenging parts of continuous improvement. With numerous document versions and platforms, consistency is paramount, otherwise the improvements get lost in translation.

Bhatnagar and his teams have found an optimal solution, “Dozuki allows us to document what we do in text, photos, and videos. We state that this is the current known best practice, if you find a better way, great, let’s upgrade it.” Shares Bhatnagar, “Then we create and share those changes with everyone, making sure users are trained the same way and on the same page. Eliminating variations in work and duplicating the best known practice across facilities is the ultimate goal.”

Creating Results

Continuous improvement is a great way to recognize opportunities and implement improvements into the day-to-day operations of the company. Bhatnagar shares one final piece of advice, “Encourage people to read procedures, interact with them, and find areas for improvement—it’s the only way you get better.”

Once the culture of continuous improvement becomes second nature, your teams will begin to find opportunities in the even the most unexpected places, producing an environment that creates innovation and a sense of ownership and value among individuals. Most importantly, it creates a culture focused on creating results, and what company wouldn’t want that?

Learn more with our free resource kit >

Welcome to Dozuki

Documentation Software for Your Entire Team

Version Control

Trust that users have the most up-to-date versions and archive your work.

Photos & Videos

Promote consistency and avoid confusion with native support for photos and videos.

Data Capture

Insert customizable prompts and stream information with real-time dashboards.

Built-in Feedback

Commenting allows users to make suggestions and note inconsistencies.

Custom Approvals

Gather necessary signatures and reviews, so you can push out updated content—fast.

Multilingual Support

Translate across over 80 languages, making it easy to communicate with global teams.

Topic(s):

Continuous Improvement

,

Standard Work

,

Success Stories

,

Frontline Digital Transformation

Related Posts

View All Posts

Continuous Improvement

Implementing Continuous Improvement with Dozuki

3 min read

Is your company interested in reaping the benefits of continuous improvement (transparency, efficiency, cost reductions, etc.) but aren't sure where to begin? Dozuki has you...

Continue Reading

Continuous Improvement

Book Club: “The Joy of Lean”

6 min read

The Dozuki book club is your go-to place for industry books and resources. Our team curates knowledge from industry experts, letting you identify key takeaways and start...

Continue Reading

Continuous Improvement

Lean, Six Sigma, and Quality Management Systems

4 min read

Six Sigma, Lean, and Quality Management are distinct approaches to reducing waste, defects, and providing value to the customer. With so many approaches to process...

Continue Reading