Discover how General Mills reduced overall training time by 62% with Dozuki.

Learn MoreDiscover how General Mills reduced overall training time by 62% with Dozuki.

Learn More

For almost 100 years, this company has been one of the leading manufacturers of construction and mining equipment, diesel and natural gas engines, industrial gas turbines and diesel-electric locomotives.

Through its subsidiaries and dealers, they market and sell their products around the world as one of the leaders in the equipment manufacturing space.

To achieve its strategic goal, the company needed to digitize and share standardized processes with operators to minimize waste and control machine setups and changeovers.

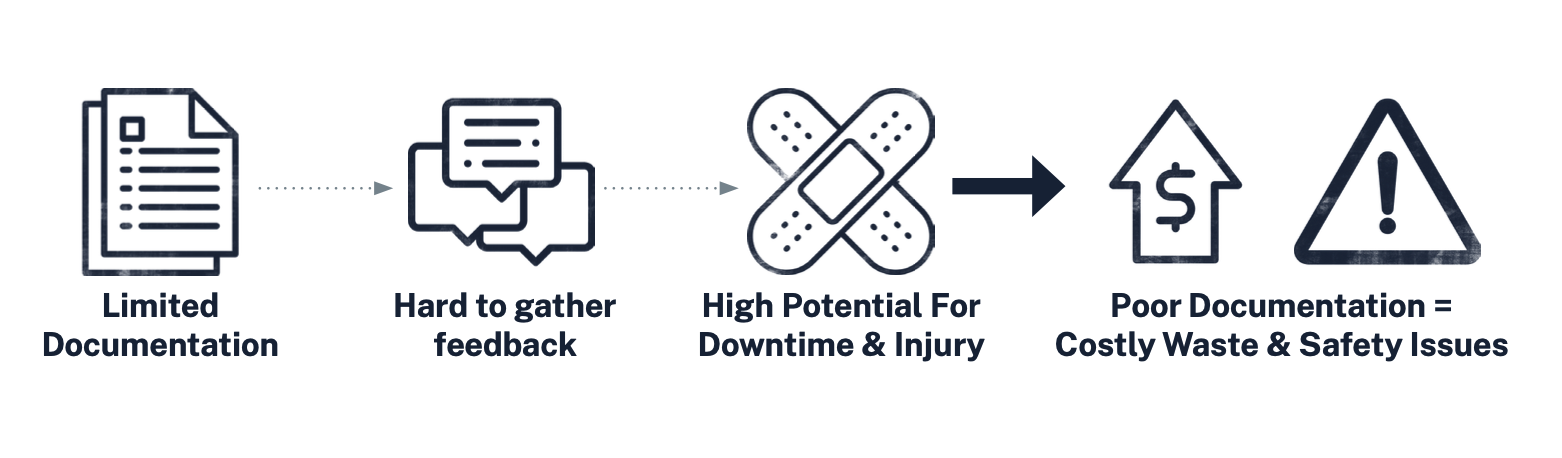

With the limited number of existing documentation, frontline workers found it difficult to share their feedback in order to improve operations. Previously, they were using Excel to create and store process information, many of which contained upwards of fifty pages of information to read and retain.

By using Excel, they also lacked the ability to gather and implement frontline feedback, missing out on invaluable insights into how operations can be improved along the way. Tribal knowledge was the norm.

The initial goal was to correct inconsistencies in production and prevent rework. Job shadowing as a primary training method was leading to competency gaps between employees. Another significant factor was safety. With the high potential for injury on the frontline of their foundries, the customer needed a solution to ensure with absolute certainty, so all employees had a clear understanding of safety protocol and best practices.

In bringing in new automation technology into the facilities, this company needed to ensure standards were properly distributed to frontline operators to better maintain, support, and utilize the new hardware.

Without Dozuki, the investment in automation would have led to significant downtime because there would have been no way to train frontline operators without production stoppage.

With Dozuki, the customer was able to leverage our digital transformation services to rapidly create, digitize, and deploy standards in a format that all employees could easily understand.

The manufacturer also lacked restrictions on who could access the documentation, which led to duplication, accidental deletion, and extra document handling. This was a lengthy process where updates to standards took weeks for approval, often getting physically lost in the process. Even upon completion, documents were rarely utilized on the floor. Workers generally were not comfortable navigating network drives, and spreadsheets were widely panned as confusing.

With Dozuki, operators could access content directly from the floor with a QR code scan, even in the extreme environment of the forge. Ensuring the right content is in front of the operators at any given time was critical to reducing mistakes and quality issues.

The customer’s old approval process (for moving process changes into production) involved too much back and forth between screens multiple times to review changes. This effort was very time consuming and confusing.

In Dozuki, operations stakeholders have a purpose-built document control system where they can see the full list of process documentation that needs approval, allowing them to quickly update content on the fly and instantly distribute it to operators on the frontline. It even includes a built-in audit trail to track all changes in case they need to be reverted.

“I was impressed with how the approval workflow provides a breakdown and a clear image of exactly what changed within a revision,” said the Supply Chain Engineer.

He was blown away by the ease of use of Dozuki, improved visibility, and the increased accountability when a user reviews the change.

Dozuki helped the customer implement an Autonomous Maintenance Checklist (AMC). The previous process caused 2-8 hours of machine downtime 3 times per week. After the implementation of the new AMC, the lines ran smoothly and safely for over three weeks straight with ZERO downtime.

Downtime

Saved per hour

Process Revisions

Faster

Annual Equipment Repair

Saved per machine

Annual Savings

Per line