Frontline Digital Transformation

5 min read

OSHA's Recommended Strategies for Improving Safety Programs

Workforce safety is non-negotiable for any industrial business. When mistakes can cause serious harm or bring operations to a halt, companies can’t afford to take safety lightly.

However, according to the National Safety Council, a worker in the United States is injured on the job every 7 seconds. Among the top offending industries, manufacturing ranks as the 3rd highest.

Based on decades of research, OSHA published strategic recommendations for companies to improve their health and safety programs. As proven strategies, key principles include:

- Leadership Communication & Support: Managers are responsible for leading and communicating the vision for a health and safety program. Provide the proper tools and information for employees to be safe and healthy while meeting their workplace expectations.

- Education and Training: An effective training program is at the core of any safe workplace. This gives workers the knowledge and skills needed to perform safe work and avoid creating more risk. Safety training programs also teach workers how to identify new hazards and report incidents.

- Hazard Assessment and Prevention: Employers must take steps to proactively identify hazards and areas of risk. Workers often have the best understanding of conditions that creates hazards. Therefore, workers must be involved when assessing past incidents and take an active role in improving conditions to prevent future incidents.

- Worker Participation: Employee feedback should be taken seriously and participation encouraged. Buy-in from all levels of the workforce fosters a safety program that thrives on excellence and improvement.

Dozuki is built to improve the safety, health, and efficiency of manufacturing operations. By accelerating communication and increasing the flow of knowledge, we empower companies to train to higher standards and solve problems faster.

Leadership Communication & Support

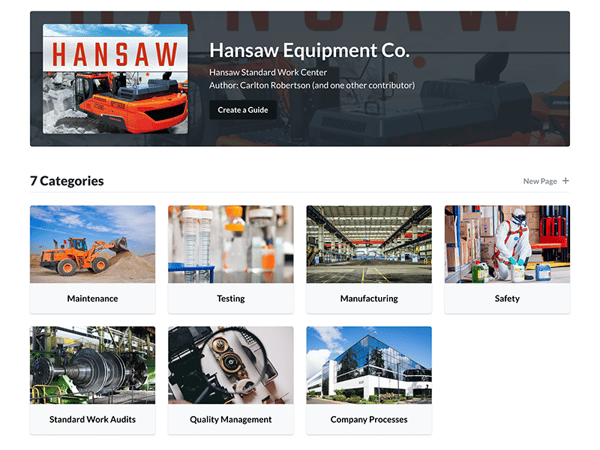

Effective communication is central to any successful health and safety program. Hundreds of industrial companies trust Dozuki for this purpose. With a centralized category structure, Dozuki acts as a knowledge hub for companies, with easily searchable safety procedures, work instructions, training, and more.

Frontline workers can quickly access documented health and safety information in any work environment via QR codes. In addition to being easy to access, it’s also heavily controlled through purpose-built document control features. Trust that workers are only accessing accurate, approved procedures — every time.

Education and Training

Traditional training programs are falling behind. Due to a shifting workforce and higher turnover rates, companies need training programs that can adapt. The more knowledge your employees have at their disposal, the more capable they will be at performing their work safely.

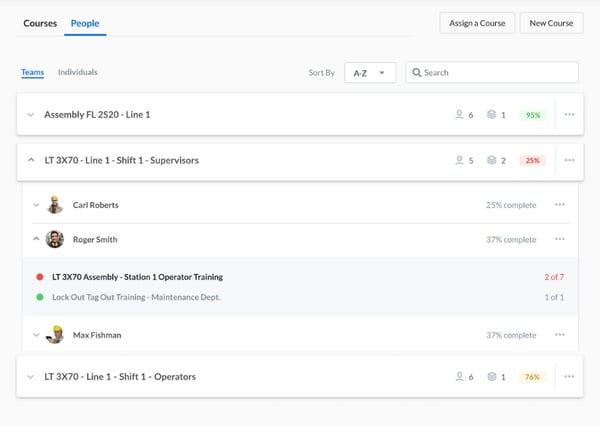

Visual training using Courses in Dozuki allows companies to tie training curriculum directly to controlled standards, ensuring that workers are trained to the most accurate safety information. Management can assign training to groups or individuals, track progress, and automatically require retraining when safety standards are updated.

We’ve helped customers with 100% workforce turnover rates maintain a fully trained workforce.

Hazard Identification and Assessment

Unfortunately, mistakes do happen. But problems are often solved in isolation, preventing others from learning from past mistakes.

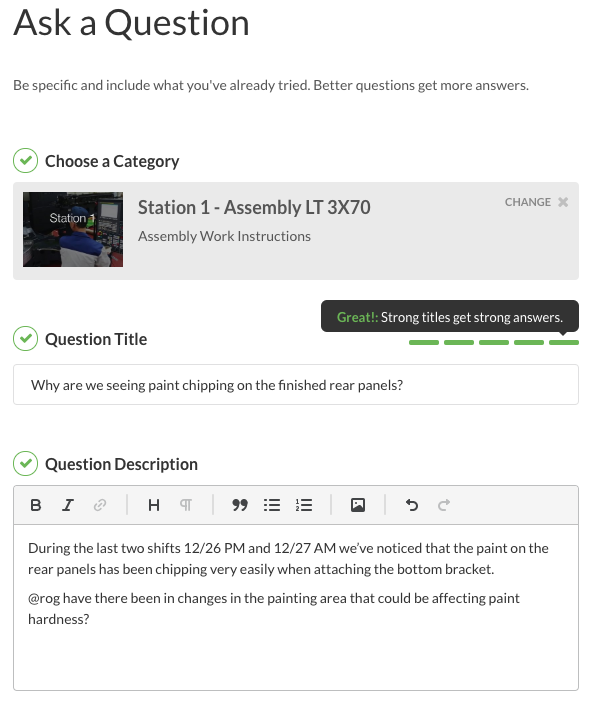

Using Answers in Dozuki, problem-solving is centralized and provides transparency when solutions are identified. When a user asks a troubleshooting question, they are automatically notified when others respond with a solution, which can then be reflected in an update to the documented procedure for others to benefit from in the future.

Worker Participation

The best way to improve health and safety is to give workers the ability to provide feedback and contribute to the program. Your workforce is full of individuals with untapped experience and knowledge waiting to be leveraged.

With Dozuki, workers can provide insights directly within procedures. This enables companies to gather feedback straight from the floor, from your experts on the frontline. In addition to gathering feedback, Dozuki is built to continuously improve workforce safety through intuitive digital forms, built into safety procedures.

Build Better Safety Programs with Dozuki

The bottom line — safety revolves around communication. Using Dozuki, manufacturers can make safety information standardized, accessible, and easier to communicate.

Our tools give you the power to take safety to the next level. Learn more about how Dozuki improves workforce safety and training.

Topic(s):

Frontline Digital Transformation

Related Posts

View All Posts

Training

Deadly Instructions: Using Visuals to Train Safely

7 min read

In 2016 OSHA reported 2.8 million workplace injuries, with 440,000 of them occurring in the manufacturing industry alone. For manufacturers, that means for every 100 workers,...

Continue Reading

Work Instructions

How to Get More Out of Your Work Instructions

6 min read

When leveraged properly, standardized work instructions can transform operational efficiency, quality management, employee performance, and more. All industrial businesses...

Continue Reading

Work Instructions

5 Instant Benefits of Digital Work Instructions

5 min read

Unlike other digital transformation projects, making the simple switch from paper-based work instructions, SOPs, and other documentation to digital work instructions provides...

Continue Reading