Your New Benchmark For

Work Instructions Software

Upgrade your workforce with a smarter way to create, control, and communicate procedures with standard instructions.

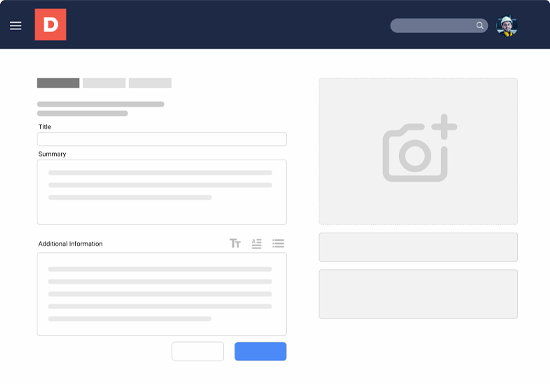

Standard Authoring

Industry proven procedure templates ensure documents maintain consistency regardless of who created them. Authors can work faster knowing they are following a standard format by default.

Industry proven procedure templates ensure documents maintain consistency regardless of who created them. Authors can work faster knowing they are following a standard format by default.

Industry Proven Templates

We've helped millions of people learn technical procedures and have folded those lessons into how we built our work instruction software.

Standardized Across the Organization

It doesn't matter who is authoring your work instructions — they will all look the same. This allows for faster comprehension and improved clarity on the frontline.

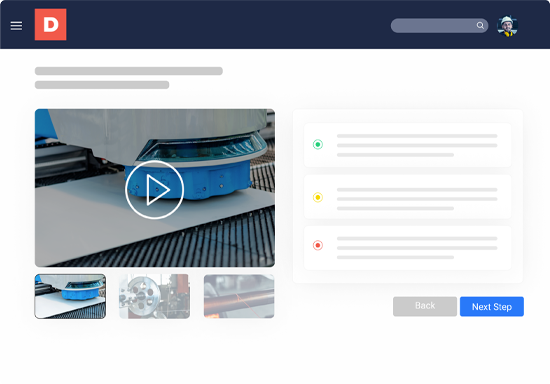

Video Instructions

Include video of how-to complete any procedure to turn complex concepts into simple visual instructions. Capture video on the floor or in the field and instantly include it in your work instruction.

Include video of how-to complete any procedure to turn complex concepts into simple visual instructions. Capture video on the floor or in the field and instantly include it in your work instruction.

Breakdown Videos

Record brief videos to augment photos and written steps in the work instruction software.

Faster Comprehension

Mimic modern tools like Youtube with video-first instructions that appeal to the incoming, younger generation of manufacturing workers.

“

After comparing Dozuki to other options, it became a clear choice. The system is so intuitive and easy to kick-off... just like navigating a website.”

– Lead Manufacturing Engineer

Boom Supersonic

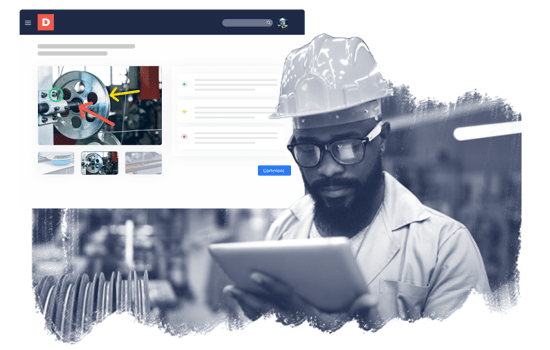

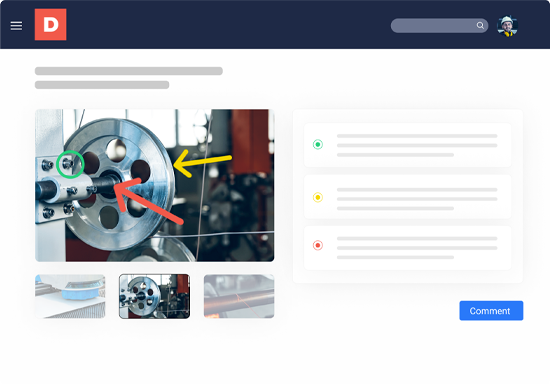

Communicate in Detail

You don't need a separate application to edit and annotate images — with Dozuki, it's built in. Use color-coded image markup and special bullets to annotate complex procedures in an easy to understand format.

In-line Markup

Add callouts to any image while authoring the applicable step.

Visual Cues

Use color coded bullet points as a frame of reference for associated image markup.

Symbol Control

Customize the iconography to denote important considerations across steps.

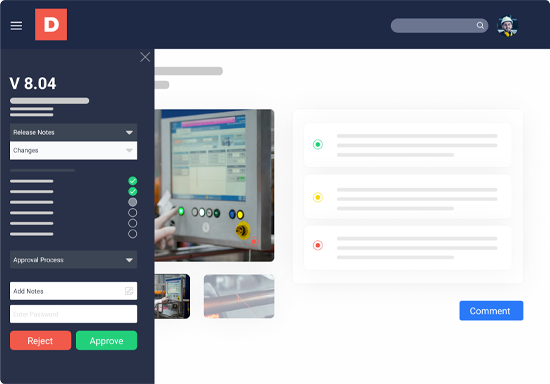

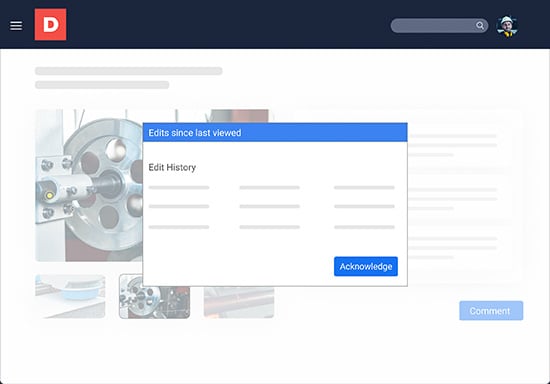

Document Control

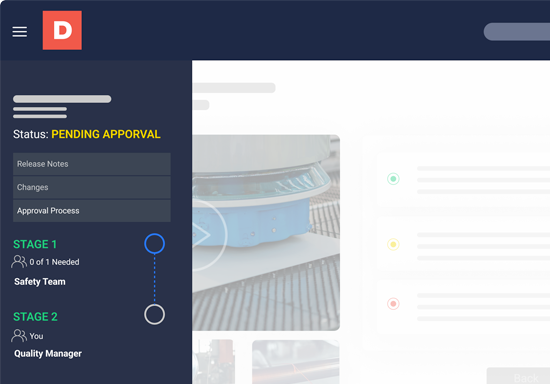

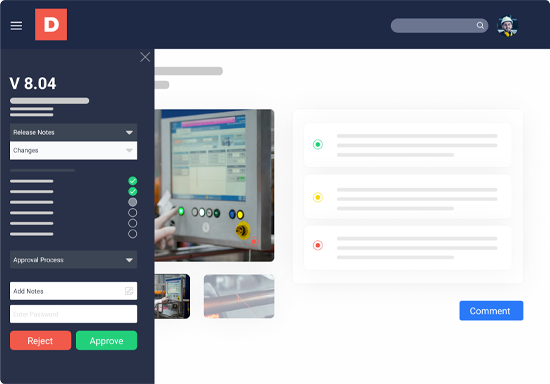

Rest easy knowing you can roll-back to previous versions and view the change history of any documented procedure. Track, approve, and release new versions of instructions with custom approval workflows — ensuring changes are approved.

Automated Workflows

Require that changes are approved by specific staff prior to release.

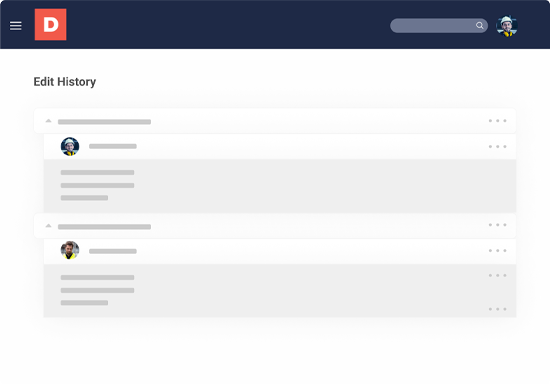

Revision History

Trace every edit made to your standards, down to the author, date, and detail.

Team Oversight

Include teams in the document review process to assure alignment on updates.

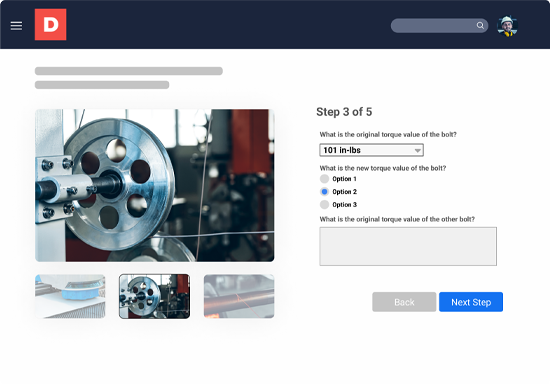

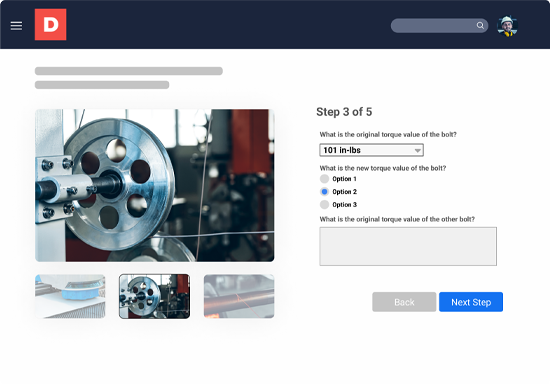

In-Line Data Capture

Gather essential information from process workers directly within your work instructions. Collect data such as work order numbers, quality check values, or supervisor sign-offs — during the procedure.

Gather essential information from process workers directly within your work instructions. Collect data such as work order numbers, quality check values, or supervisor sign-offs — during the procedure.

Supervisor Sign-Off

Require a supervisor to sign-off electronically at any stage of a procedure.

Quality Checks

Collect data values in-procedure to capture critical information about the work order.

Data Export

Easily export data from directly within Dozuki or via API to your external systems.

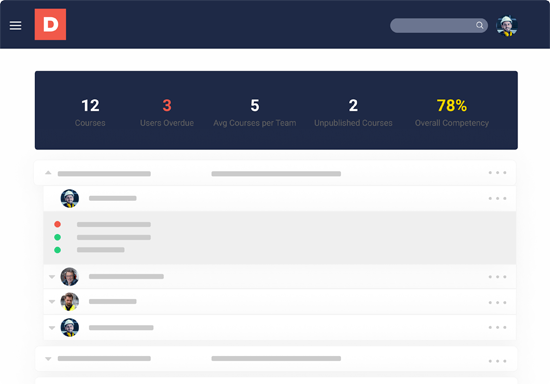

Standards Training

Turn your standard work instructions into curriculum and instantly view who is trained to the latest version. Automate the re-training of workers when documented standards or employee roles change.

Turn your standard work instructions into curriculum and instantly view who is trained to the latest version. Automate the re-training of workers when documented standards or employee roles change.

Operational Training

Combine groups of work instructions into structured training curriculum.

Enforce Standards

Turn your standards into a robust and controlled training program.

Skill Tracking

Monitor the competency of your entire workforce against documented standards.

Ongoing Improvement

Integrate a feedback loop to capture process knowledge from your experts on the front-line. Allow workers to provide suggestions for process improvements from directly within any step of a work instruction.

Integrate a feedback loop to capture process knowledge from your experts on the front-line. Allow workers to provide suggestions for process improvements from directly within any step of a work instruction.

Get Buy-In

Give operators the feeling of ownership in improving your operations.

Organic Feedback

Capture feedback directly from those who do the work everyday.

Capture Expert Knowledge

Surface the tribal knowledge of your experts directly from your procedures.

Instant Distribution

Ensure everyone is working-from and training-to the latest standard, from the floor to the field. Upon approval, work instructions are instantly updated across your entire workforce.

QR Code Access

Let users scan QR codes for rapid entry to any procedure or work order.

Easy to Access

Built in search allows users to find key information quickly.

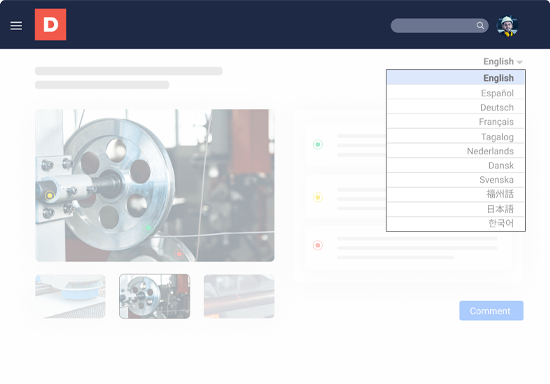

Multilingual

Built-in translation tool put procedures in your workers preferred language.

Built for Audits

Achieve and maintain ISO 9001 certification with a fully compliant document and training management solution. Give ISO auditors visibility into specific documentation, including full version histories.

Version Control

Workers can only access the current standard, and you can access every previous version.

Traceable Training

Know exactly which version of a standard any worker has been trained on.

Collect E-Signatures

Title 11 compliant electronic signatures assure sign-offs are secure and trustworthy.

“

Updating work instructions with a phone on the fly has been really helpful. Before it would have taken an entire day to update an instruction, now we can do it on the fly from the floor.”

– Brad Matthews

Industrial Engineer, Husqvarna

Common Use Cases

-

Preventative Maintenance

-

Quality Checks

-

Lock Out Tag Out

-

Production Assembly

-

Equipment Changeovers

Purpose-Built Features

Work instructions don’t just standardize work, they also prevent accidents. Give your team members all the information they need to stay safe.

Approval Workflows

Control which users approve process changes

Approval Workflows

Create, edit, and maintain all approval processes for your site content to ensure multiple points of quality assurance are involved in updating processes.

Revision History

Detailed audit trail of every approved change to processes

Revision History

Get an in-depth view of every process change, with data on who made edits, approved changes, and more. Easily revert back to any previous state.

Document Control

Oversight into creation, review, and release of processes

Document Control

Build, edit, and monitor your approval workflows and releases. Specify which users should review and approve or reject new versions.

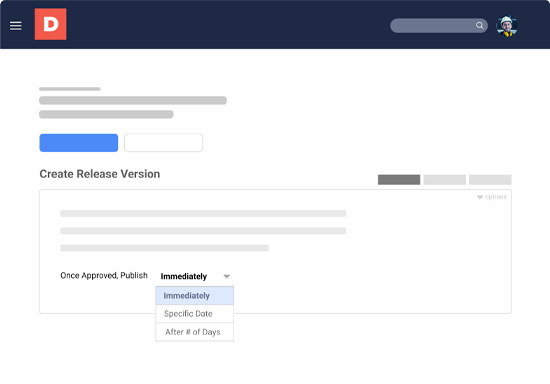

Scheduled Releases

Schedule document updates for future release

Scheduled Releases

Schedule updates to processes in the future, so users are able to train on the new processes before they go into production.

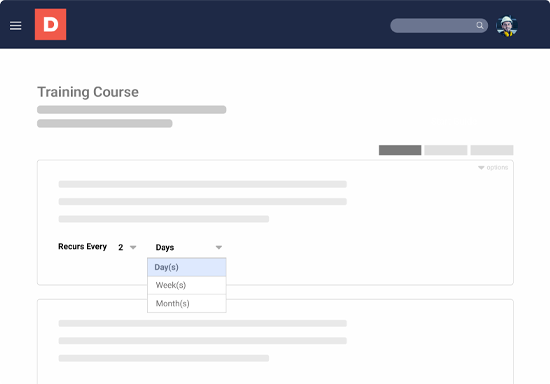

Automatic Re-Training

Recurrence of training when processes change

Automatic Re-Training

Control retraining requirements for your users. Set recurrence options for each stage of a training course so users maintain proficiency when updates are made.

QR Codes

Instant access to processes with one quick scan

QR Codes

Give your users easier access to processes by scanning QR codes attached to machines or workstations that instantly pull up all applicable process documentation.

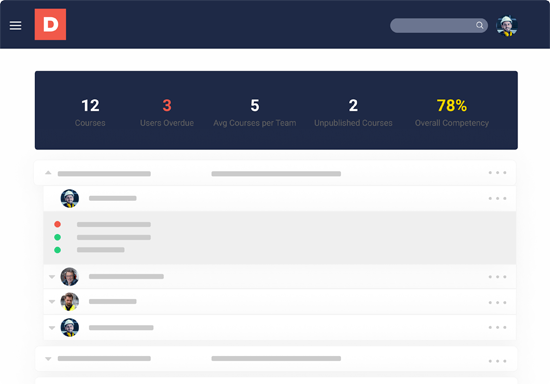

Training History

View records of training assignment and completion

Training History

Get instant visibility into which workers are trained to the latest process standard. Manage course assignments while monitoring user competency.

Wiki Pages

Collaboratively author critical knowledge across operations

Wiki Pages

Use wikis to convey general information to your workforce in a flexible format, like a troubleshooting page, internal policy, or a material safety data sheet.

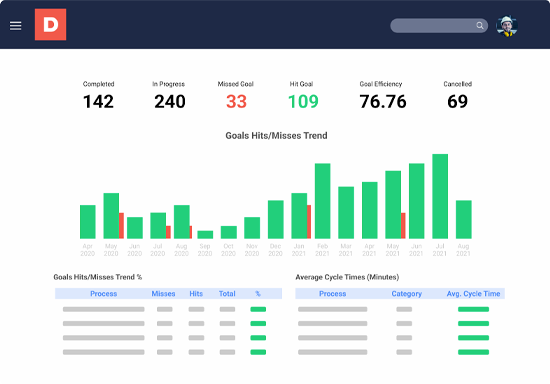

Dashboards

Optimize performance with customizable data analysis

Dashboards

Monitor your operations performance with a full set of dashboards providing insight into user activity, tracked and untracked processes, average cycle times, and much more.

Digital Forms

Collect quality checks, sign-offs, and more

Digital Forms

Capture critical information, track performance, and ensure supervisors are involved in sign-off processes with digital forms integrated directly within processes.

Languages

Instant translation across 100+ languages

Languages

Display processes in over 100 languages instantly. You can also manage your own glossary of translations to be applied to processes.

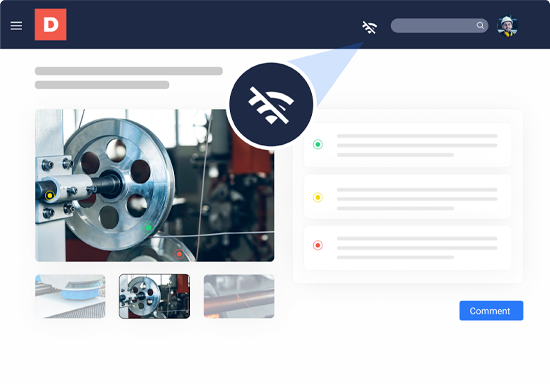

Offline Access

Uninterupted access to processes in any environment

Offline Access

Get quick and easy access to processes from anywhere, even in industrial environments with limited or no connectivity options.

Single Sign-On

Authenticated access through in-house security systems

Single Sign-On

Use third-party programs to authenticate users into your site so you can avoid having to manage user information in multiple systems.

Photos & Videos

Improved clarity and comprehension of processes

Photos & Videos

Apply images, videos, and documents in your step-by-step processes to ensure workers are never confused.

Markup Tool

Clarify images with color coded callouts and symbols

Markup Tool

Emphasize details in your images with color-coded markers and callouts to form circles, squares, arrows, and lines that add clarification to processes.

Integrations

Connect operations data to other enterprise systems

Integrations

Use our API or webhooks to create real-time integrations between our platform and other software systems. Easily connect Dozuki to your LMS, QMS, ERP, or any other systems where you need visibility into critical operations data.

External Courses

Import SCORM training content from your other systems

External Courses

Bridge the training needs of multiple departments by importing SCORM content from external systems as key components of your Dozuki training courses.

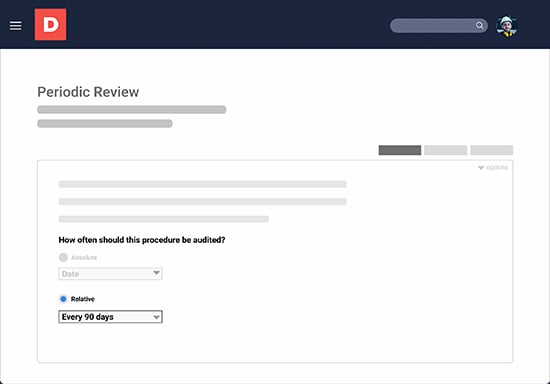

Periodic Review

Schedule recurring review of your documented processes

Periodic Review

Leverage automated review scheduling, ensuring processes are continuously audited and current.

Change Aware

Communicate process changes to users prior to work

Change Aware

Require users to review and acknowledge process changes, prior to starting their work.

Trainer Assessments

Enable trainers to assess competency over the shoulder.

Trainer Assessments

Trainers can assess the proficiency of employees in performing the processes they have been trained on, and track their competency within any assigned training course.