Continuous Improvement

24 min read

11 Essential Workplace Safety Tips for a Secure & Healthy Environment

Workplace safety is a topic that businesses simply cannot overlook. For one thing, employers have an obligation to their employees to provide a safe work environment and to take certain precautions regarding things like preparedness.

Table of Contents

1. Benefits of Prioritizing Workplace Safety

2. Importance of Workplace Safety Culture

3. Hazard Identification and Risk Assessment

4. Emergency Preparedness & Response

6. Personal Protective Equipment (PPE)

9. Workplace Violence Prevention

10. Ergonomics & Injury Prevention

11. Hazardous Materials Handling

12. Mental Health & Well-Being

Failing to do so leaves employers open to liability and workers exposed to hazards and risks for potential injury and even death.

Secondly, today's workers are much less likely to face unsafe working conditions. As hard as it is to find skilled workers in today's labor market, companies that fail to provide for their employee’s health and safety only make it harder on themselves.

And that’s not even mentioning that unsafe working conditions lead to missed shifts and lower productivity for the company.

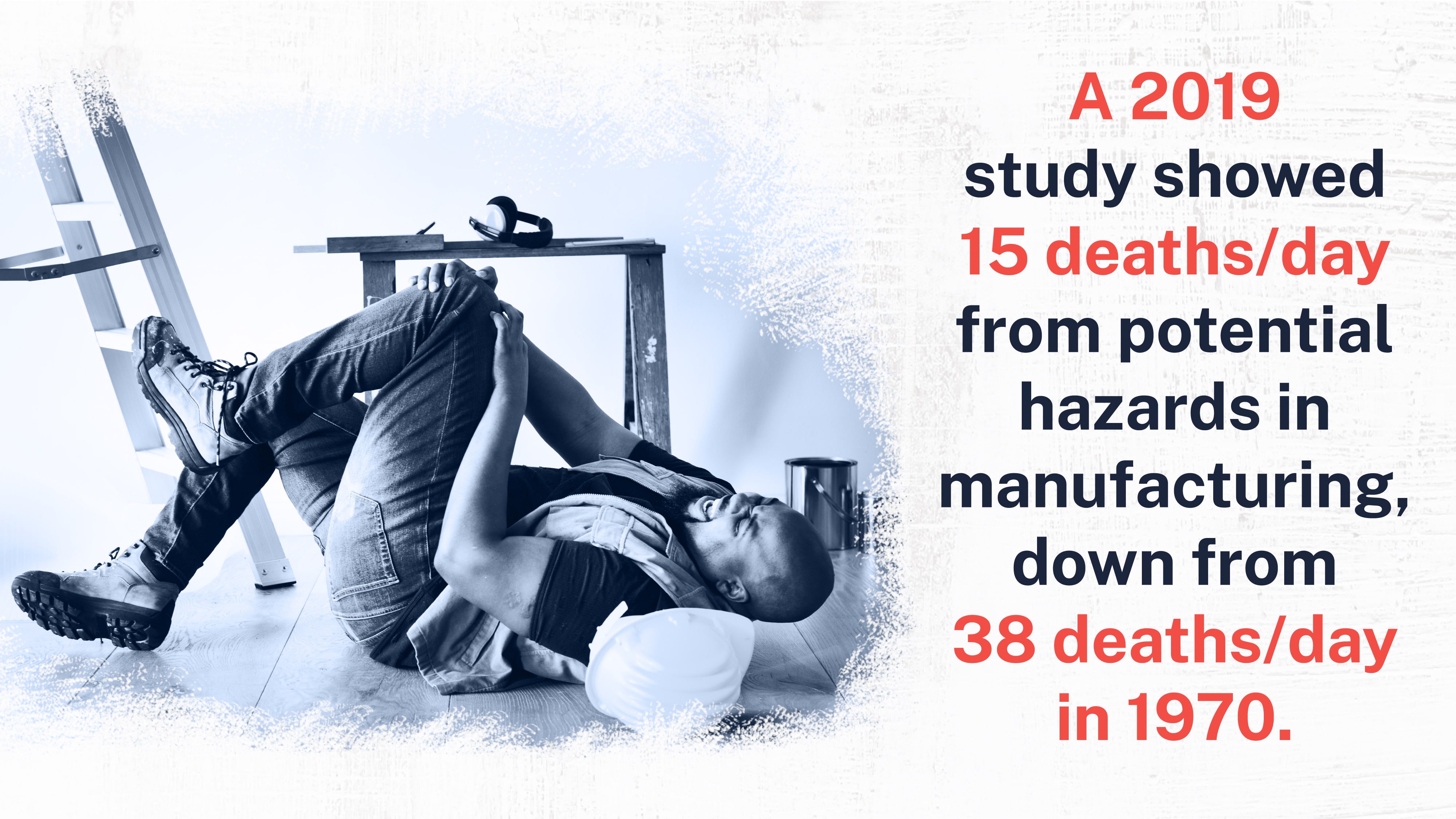

Manufacturing facilities are filled with potential hazards – from trips, slips, and falls to toxic chemicals, electrical and fire risks, and many more. Thankfully, an increase in governmental oversight and regulation has saved the lives of hundreds of workers over the years.

In 1970, the U.S. saw an average of 38 on-the-job fatalities per day. In 2019, that number was just 15 per day – an improvement, but not enough of one.

As for workplace injuries, the numbers have improved over the years but are still quite shocking.

Recent statistics show that every second, an average of 14 workers in the U.S. suffer a workplace-related injury. In 2021, there were 2.62 million non-fatal workplace safety incidents and 5,190 fatal incidents.

Workplace safety is a topic that will never go away and always deserves attention. That’s why we’ve compiled a list of 11 essential workplace safety tips to help manufacturers ensure they’re making every effort to keep their facilities safe. Let’s get started.

Benefits of Prioritizing Workplace Safety

Before we get into our list of workplace safety tips, let's look at the benefits companies can gain by putting them into action. Promoting a safe working environment benefits everyone at every level of an organization, from the top down.

Here are a few of the most significant benefits:

Improved Health, Safety, and Wellness

The most significant advantage of workplace safety comes from a better working environment for employees. Organizations that implement a well-designed safety system and train employees on what to do during emergencies reduce workers' risk of injury and illness. It also has a direct effect on their mental health and well-being. And it protects resources, equipment, and even customers.

Cost Savings

An unsafe working environment is costly for organizations for several reasons. Accident-related expenses like lost wages, medical expenses, legal fees, and higher insurance premiums add up quickly in a large organization.

Better Employee-Employer Relations

Employees working within an organization that puts time and effort into keeping them safe are likelier to stick around. Employees want to work where they feel safe, and they appreciate it when their employer takes steps to build a safe working environment.

Increased Productivity

Workplace-related accidents put a stop to productivity, literally. The immediate effects are missed shifts and the need to fill roles on short notice. But an incident or injury can also slow the progress of an entire facility. And a reduction in accidents is sure to keep employees happier on the job – a scenario that leads to a 20% boost in productivity.

Importance of Workplace Safety Culture

First on our list of workplace safety tips is the organization's culture. Building safety into the fabric of a company is key to getting everyone on the same page.

A workplace culture involves everyone on the team, from operators to managers – and must start from the very top. Organizations must create an environment where everyone understands that safety is taken seriously and that compromising is out of the question.

When workers know their employers are trying and spending resources to keep them safe, they’re more likely to follow rules and safety procedures. And they’re more knowledgeable about what to do in an emergency and how to keep themselves safe on the job.

On the other hand, organizations that fail to build a fabric of safety in their procedures put workers at risk. When workers aren’t trained correctly and are not held to a high standard, complacency is allowed to manifest, leading to an increase in accidents and injuries.

Hazard Identification and Risk Assessment

Next on our list of workplace safety tips is hazard identification and risk assessment. Every manufacturing facility is different. There are different types of machinery, materials, and procedures, each with unique risks.

On top of that, there are some common risks and hazards that all facilities face, such as the risk associated with slips, trips, and falls.

Hazards can take many forms, from critical to every day. Identifying, assessing, and communicating hazards is the best way to combat them. The categories of hazards include:

- Biological

- Chemical

- Physical

- Ergonomic

- Safety

- Psycho-social

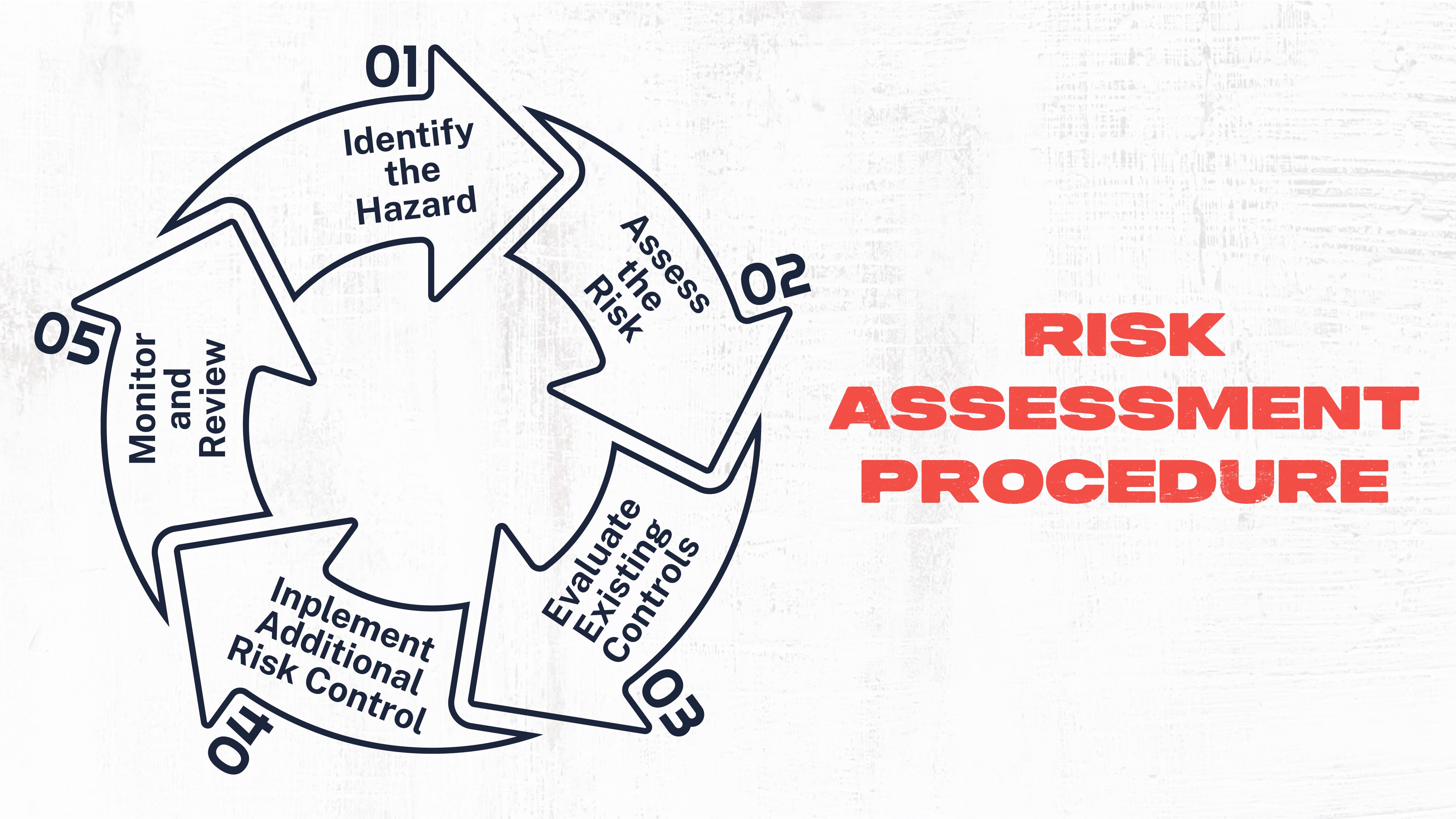

To build safety standards that work well, organizations should perform hazard identification and risk assessments. This will help identify and prioritize potential hazards and ensure that supervisors and operators are aware of them and trained to avoid them.

Hazard identification and risk assessment should be a multi-step process, including preparation and follow-up. It includes things like:

- Recognizing and understanding hazards

- Assessing risk levels

- Controlling hazards by prioritizing and implementing strategies

- Documenting assessments and incidents

- Ensuring the efficacy of control strategies

It’s important to note that hazard identification is slightly subjective, as workers will evaluate risks differently. Workers should be trained to evaluate their workspace before starting any task. This will allow them to identify and rectify potential hazards before they become problematic.

Emergency Preparedness & Response

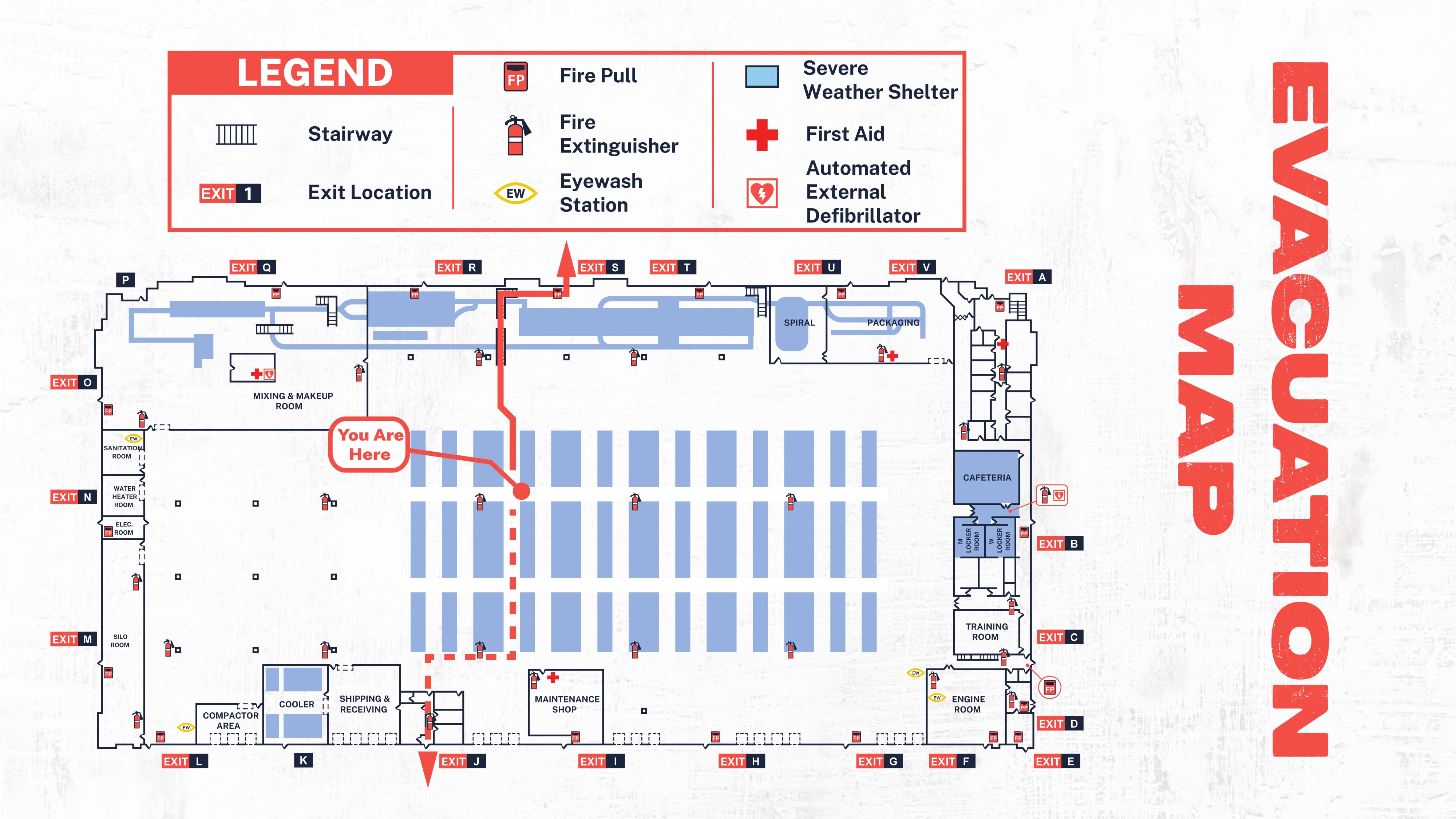

Any list of workplace safety tips must account for emergencies and preparedness. Dangerous situations can arise quickly and without warning, and employees must be equipped with knowledge and training in what to do in those moments. Things like fires, chemical spills, equipment collapse, severe weather events, and others require employees to know and understand how to react quickly.

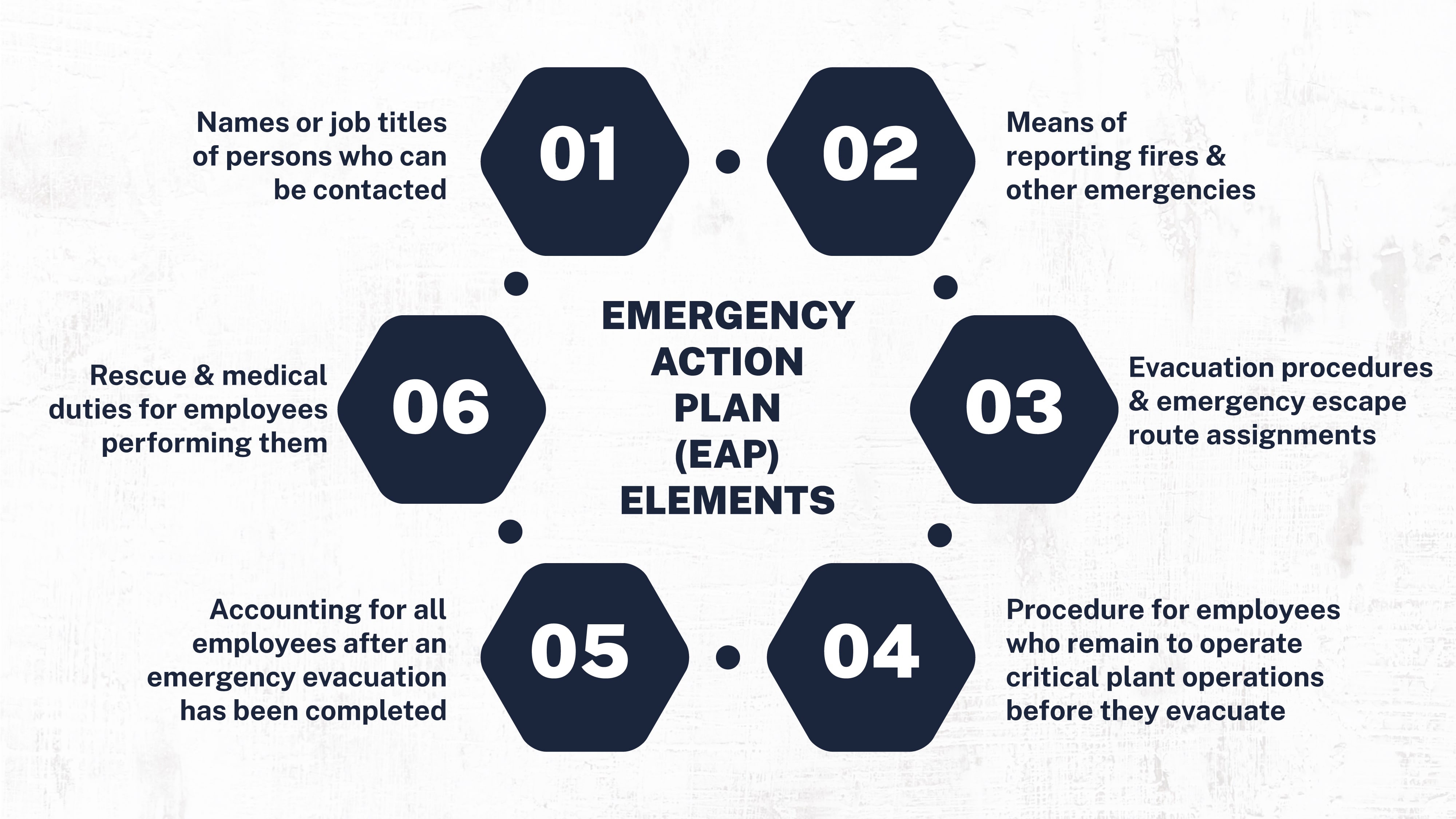

Some rules and regulations require specific organizations to create and implement an Emergency Action Plan (EAP), and rules about what kinds of information it should contain. But in general, organizations should put together a comprehensive action plan for every potential hazard, especially those that could lead to serious injury or risk to human life.

Organizations should make and communicate a plan for every potential emergency. To do that, they must:

- Identify and assess hazard risks.

- Develop a step-by-step plan that addresses each risk.

- Train employees on how to identify hazards, respond to them, and use PPE in emergencies.

- Run emergency drills to test employees' understanding of procedures.

Additional Emergency Preparedness Tips

- Organizations should make it commonplace to update and review emergency preparedness plans.

- Designate and communicate emergency contacts for coordinating quick responses across the facility.

- Ensure employees have access to and knowledge of emergency equipment, such as fire extinguishers, first aid kits, and personal protective equipment.

- Train and retrain employees on emergency action plans and responses.

- Maintain and test the performance of emergency equipment.

- Keep careful records, including lists of emergency contacts, potentially hazardous materials, building plans, emergency exit routes, and incident reports.

Safe Work Practices

Sometimes a workplace hazard is apparent. Other times it’s something workers might not even recognize as dangerous immediately. Because of the nature of the work performed, manufacturing facilities are ripe for these types of “hidden hazards.”

Our next workplace safety tip is for employers to make every effort to ensure workers have a safe working environment. And to ensure employees understand how to keep themselves safe from these risks on the job. Not only is it the right thing for employers to do, but it is legally mandated that organizations provide a safe workplace and eliminate these types of risks.

Ergonomics and Safety

Ergonomics refers to the practice of considering the worker's needs when designing workspaces. For example, a proper and safe workstation setup can prevent injury. If an employee is forced to maintain an awkward body posture or repeatedly bend or twist while working, it can quickly result in a physical injury.

Tools and Equipment

Using the right tools and equipment and ensuring they’re in proper working order can prevent many accidents. Tools should be maintained and tested to ensure they are working well.

Provide Frequent Breaks and Reasonable Expectations

Ensuring employees have access to frequent breaks throughout the day can combat fatigue and corner-cutting. Putting pressure on employees to meet unattainable deadlines or output goals can lead to rushing and bypassing safety standards.

Enforce Proper Lift and Carry Technique

Statistics show that over 20% of all workplace injuries result from overexertion when lifting, pushing, pulling, or carrying. These actions can cause injury immediately if performed incorrectly or lead to injury if performed repeatedly. Employees should be trained in proper lifting techniques and counseled to avoid lifting amounts that are too heavy or dangerous.

Understand that Safety is a Legal Requirement

OSHA requires every employer to provide employees with a working environment “free from recognizable hazards that are causing or are likely to cause death or serious physical harm.” This means that providing resources and tools to keep employees safe is a moral and legal obligation for employers.

Personal Protective Equipment (PPE)

Personal Protective Equipment is designed to help keep workers safe in hazardous situations. And providing proper PPE to employees is a legal requirement for employers, especially if those employees are exposed to dangers that cannot be eliminated or controlled by other means. That’s why providing, maintaining, and training employees in using PPE is one of our most crucial workplace safety tips.

PPE protects workers from various hazards, such as chemical, biological, physical, electrical, and mechanical. It might include gloves, hard hats, safety glasses, respirators, earplugs, and shoes.

Providing proper PPE isn’t as easy as handing an employee a pair of gloves and hoping for the best. Employers must follow these steps to ensure PPE's safe use and application.

- Identify hazards that require the use of PPE.

- Determine what kind of PPE is required and when it should be employed.

- Train employees on the proper use of PPE, including how to wear it, adjust it, and remove and dispose of it safely if applicable.

- Understand what the PPE can and cannot protect against and communicate with employees.

- Care for and maintain PPE properly, inspect it regularly, and replace it when needed.

- Train employees to communicate when PPE is damaged or misused.

Fire Safety

Fire hazards are incredibly commonplace in manufacturing facilities because of machinery, tools, and even certain flammable chemicals.

Preparing for a fire emergency and taking steps to prevent them is a critical workplace safety tip because the potential for injury or loss of life is very high.

Fires happen frequently in the U.S. According to the NFPA, a fire department responds to a fire emergency every 24 seconds. That’s why fire safety is another one of our top workplace safety tips.

Fire hazards in the workplace can include:

- Flammable materials

- Combustible liquids

- Dust and debris

- Electrical equipment

- Smokers

- Negligence

Employers can combat fire risks by ensuring that the proper emergency procedures are in place and employees are trained in emergency fire response. Employees should know when and how to evacuate in a fire.

Organizations should run frequent fire and evacuation drills to test employees’ knowledge of fire emergency procedures.

Fire extinguishers should be available wherever a serious risk of fire is present. The law requires fire extinguishers to be available throughout a facility and requires regular testing and maintenance of the equipment by a fire inspector. Employees need to know the location of fire extinguishers and how to use them properly.

It’s also vital that fire protection equipment is in good working order. Fire detection and alarm systems should be in place and operable.

These systems are designed to quickly alert employees and individuals to the presence of a fire that might otherwise go unnoticed and spread. It gives workers ample time to respond and get to safety, preventing serious injury or loss of life and property damage.

Electrical Safety

Electrical safety is one of the biggest workplace safety tips for manufacturers, and it’s essential for preventing injuries and fatalities in facilities. Electrical safety is crucial because of its high use in manufacturing facilities and because of its potential to inflict fatal injury.

Because of this, OSHA has strict safety standards that employers must follow to keep workers safe from electrical hazards. It’s the responsibility of employers to follow these regulations and take steps to ensure that employees are educated on the risks of electrical hazards.

Dangers from electricity are everywhere in many manufacturing facilities. Hazards presented by overhead power lines are dangerous for vehicles.

Equipment that lacks proper ground-fault protection, or ground-fault circuit interrupters (GFCIs), puts employees at risk of electrical shock in wet or damp conditions. Damaged or improperly used power cords are a hazard. And of course, poorly maintained, or unsafe equipment is extremely dangerous for employees.

Common electrical safety standards include:

- Providing proper training and education on electrical safety.

- Test employees' knowledge and understanding of safety procedures and emergency response.

- Keep electrical equipment and tools in good repair.

- Inspect tools and electrical cords before use and replace them if necessary.

- Use lockout/tagout procedures to ensure employees aren’t working on energized equipment.

- Provide employees with proper PPE to protect them from electrical risks and train them to use the PPE correctly.

Workplace Violence Prevention

Workplace violence prevention is one of our most essential and unfortunate workplace safety tips. While many companies focus on commonplace risks like fire prevention and protection against electrical injury, workplace violence is more frequent than some realize.

According to the Bureau of Labor Statistics (BLS), workplace assaults caused more than 20,000 days-away-from-work injuries in 2020. The National Safety Council reports that millions of workers report being victims of violence in the workplace every year.

It’s a sad reality today that employers must address directly with workers.

Workplace violence can take many forms. It might be violence perpetrated by an outside person, like a robber or someone using a weapon to injure workers.

Often, it’s perpetrated by former employers, customers, or clients of a business. And sometimes, it comes from employees or someone who has a close, personal relationship with an employee.

Employers can take steps to combat workplace violence. They include things like:

- Building a company culture that values respect and civility.

- Providing employees with training to recognize and respond to potential threats of violence.

- Implementing security measures to deter and prevent violence.

- Implementing open-door policies to encourage communication.

- Employ mediation to help employees deal with workplace stress and conflict.

Ergonomics & Injury Prevention

We touched on the importance of ergonomics earlier. Still, because of its importance in preventing injury and illness for employees, we’re listing it as one of the most essential workplace safety tips. In essence, ergonomics is the science of fitting the right job to the right worker and providing a working environment and process that considers the worker’s health and well-being.

Properly applied ergonomic principles can help protect employees from developing musculoskeletal disorders, which are common injuries that affect the body's muscles, nerves, and tendons. Disorders like carpal tunnel syndrome, tendonitis, and back injury are commonplace in working environments. Manufacturing facilities are ripe with this type of injury because of the frequent bending, lifting, and twisting that employees perform on the job.

Employers can c

ombat these types of injuries by building workspaces that make the job easier and safer for employees to perform. For example:

- Ensure tools and equipment are within easy reach to prevent unnecessary bending and reaching.

- Eliminate steps from processes that result in repetitive movements when possible.

- Train employees in proper lifting techniques and employ team lifting when necessary.

- Instruct employees on the importance of stretching before beginning work to prevent injury.

- Rotate workers to prevent repeated exposure to job roles that subject workers to repetitive motion injury.

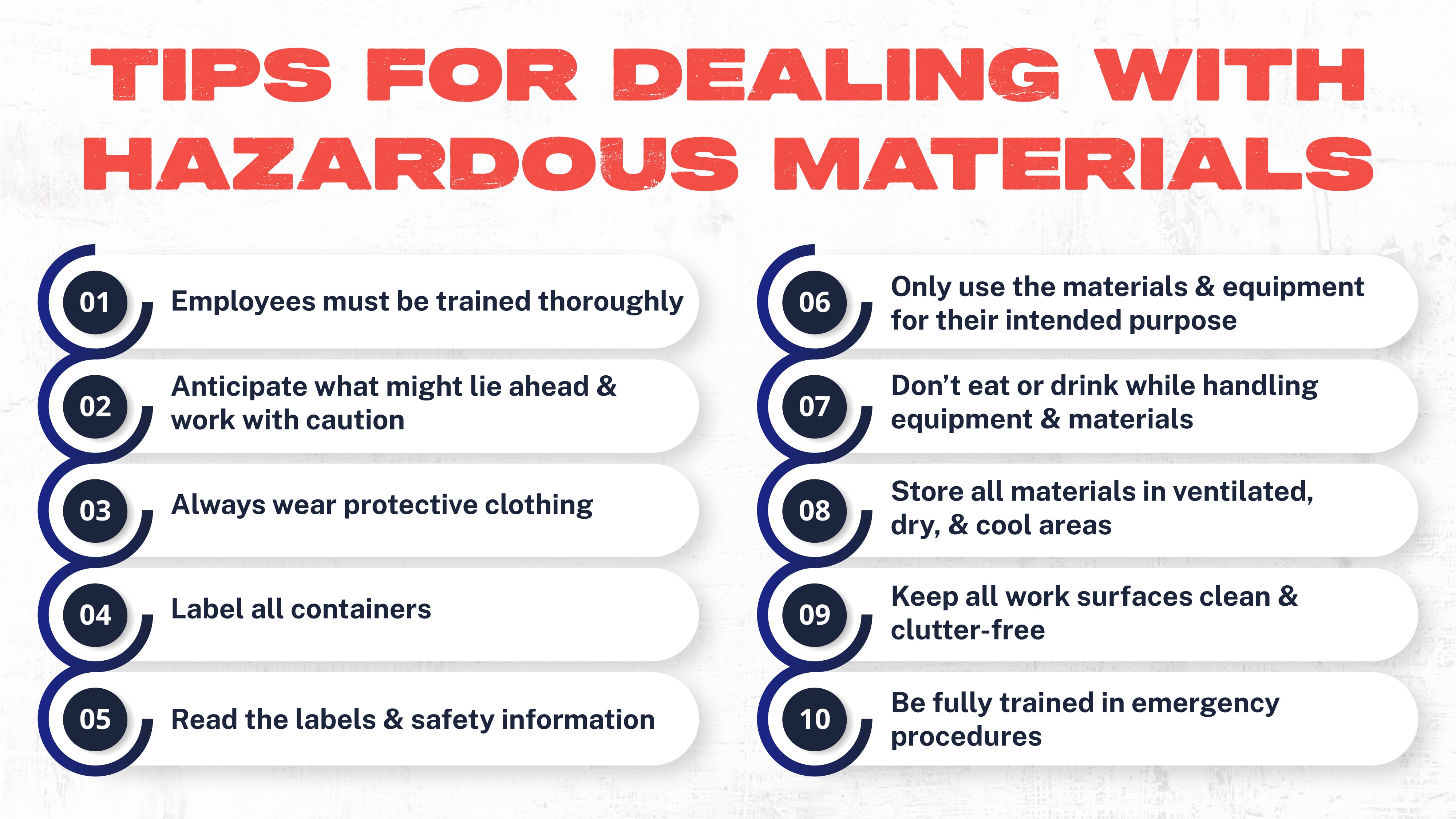

Hazardous Materials Handling

One of the most prevalent hazards in manufacturing facilities is exposure to hazardous materials. That’s why knowledge and training in safely using and handling hazardous materials are also one of the most critical workplace safety tips.

Hazardous materials can pose a serious risk to human health, safety, and the environment. Governmental agencies heavily regulate both risks, and that’s one reason employers must take precautions to protect workers and the environment from hazardous materials exposure.

Employers should build safety procedures and best practices around using, storing, handling, and disposing of hazardous materials. Doing so prevents accidents, protects workers from illness or injury, and protects the community from exposure.

Best practices for hazardous materials include:

- Identifying and understanding the risks involved with hazardous materials

- Providing employees with proper PPE and training them in its use

- Establishing hand washing and eye washing stations throughout a facility in case of accidental exposure

- Safe handling, storage, and labeling procedures

- Training employees on the proper ways to handle hazardous materials

- Keeping hazardous material lists, safety data sheets, and other documents or records

- Ensuring proper disposal of hazardous waste per government law

- Putting emergency action plans in place to address the risks of accidental exposure or spills

Mental Health & Well-Being

Finally, on our list of workplace safety tips is the importance of addressing workers' mental health and well-being. We’ve discussed physical hazards, as is common in workplaces. But the mental well-being of employees is just as important and often overlooked and stigmatized at manufacturing facilities.

It’s a fact that poor mental health can manifest itself as physical ailments, including hypertension, cardiovascular conditions, insomnia, and diabetes. And poor mental well-being quickly leads to employee burnout, a devastating scenario for workers and employers alike.

Organizations can take steps to incorporate mental health and well-being into the workplace, even in factories and manufacturing facilities. Here are some suggestions on how to do it:

- Give employees access to mental health resources, like free counseling.

- Ensure employees have information on how to reach out for emergency help.

- Create a supportive and communicative working environment for everyone within an organization.

- Respond to employee concerns with empathy and respect.

- Help employees manage stress by providing rest areas, uninterrupted breaks, and healthy snacks.

- Allow employees access to gyms or recreation rooms to exercise or blow off steam.

- Organize events for employees to socialize outside of working hours.

Final Thoughts

These workplace safety tips are just a framework employers can use to help keep employees safe and healthy. But companies must try to employ these methods every day within their facilities, and not just as a stopgap measure, but as a part of the culture of the company.

Prioritizing workplace safety should not be seen as an afterthought because its benefits extend to virtually every corner of the business. When workers are taken care of, they are healthier and can show up to work when needed. They’re more productive and engaged with their work and willing to work for the company's goals. And they can build better relationships with each other and their supervisors.

Organizations that put focus on health and safety face fewer expenses related to accidents, illness, and injuries. They are safe from regulatory fines and face fewer legal liabilities. And they build a better reputation with customers, employees, and their communities.

And most importantly, safety and wellness measures in the workplace protect employees. They protect their physical well-being, their mental well-being, and the financial security of their families. A safe workplace is not a benefit – it's a right that employees have. And it’s a requirement that employers provide it for them.

Topic(s):

Continuous Improvement

Related Posts

View All Posts

Training

6 Common Manufacturing Facility Hazards & Effective Solutions

20 min read

Manufacturing facilities serve an important function in a country’s economy, as they create jobs, increase wealth through added value and taxes, promote trade, and support...

Continue Reading

Frontline Digital Transformation

6 Strategies to Maximize Worker Safety

7 min read

In industrial companies, workplace safety is the #1 driver behind many key decisions. Not only is safety essential for protecting workers, it’s also essential for consistent...

Continue Reading

Standard Work

Best Methods to Reduce Human Error in Manufacturing

27 min read

In manufacturing, many factors need to be balanced and aligned for companies to be successful. And one of those factors includes the combination of humans and machines...

Continue Reading