Standard Work

4 min read

Free Standard Operating Procedure & Work Instruction Templates

Standard operating procedure (SOP) and work instruction templates help standardize processes and present information consistently. We’ve seen thousands of examples of these templates and the only consistency is their shortcomings.

This template collection is from those we’ve talked to over the past 7 years while building Dozuki—they’re yours to use for free. Each standardized template is accessible as Powerpoint, Excel, or PDF files.

While we don't endorse the use of spreadsheets for work instructions or SOPs, understanding previous methods for standardized work can help illustrate the potential for improvement.

In this bundle, you’ll find free templates for:

- Standardized Work Instructions

- Process Capacity Tables

- Standard Work Combination Sheets

- Time Observation Sheets

- And more...

The Importance of Standardized Digital Work Instructions

Standardized work instructions serve as a framework to facilitate and record process improvements in a formal way. The benefit of this method is that it allows for the distribution of knowledge and progress across the entire organization, enabling everyone to enter a mindset of continuous improvement and learning.

Standardizing information is a great first step to implementing standardized work, but these templates haven’t changed much since they were first introduced in the 1960s. It’s no wonder that 66% of lean manufacturers are failing to sustain standardized work.

66% of lean manufacturers fail to sustain standardized work

If you’re like most manufacturers, you’ll find these aren’t easy to use. Powerpoint and Excel files are cumbersome to use and update. Moving to an digital work instructions system can help automate standardize formats, automate revision control, and promote behaviors of continuous improvement.

The Four Pillars of Process Knowledge

Documentation can take many forms. Between work instructions and SOPs alone, there are endless variations for how to document process knowledge. That said, there are four main types of instructional content to be aware of:

Standard Operating Procedures (SOPs)

SOPs are written processes that describe in detail how to perform a work task specific to your operations. Documenting standards properly allows businesses to comply with regulatory and quality standards, train more effectively, and enable a culture of continuous improvement.

Traditional Work Instructions

Work instructions provide the same benefits of standard operating procedures, but provide more detail to the worker in order to instruct on how to complete a task with no prior knowledge. In short, work instructions are the how-to guides of your operations.

Training Materials

Training materials are closely related to work instructions, with the key difference being that you’ll want to verify that certain knowledge is retained, and that key processes or techniques are up to safety and quality standards. In this sense, data collection and supervisor signoffs are key components of training documentation.

Standard Work

Standard Work is the roadmap for all processes and business functions. Put simply, it is the living record of the best known practices at the time. In fact Taiichi Ohno, the founder of the Toyota Production System, once said, “Without standards, there can be no Kaizen.”

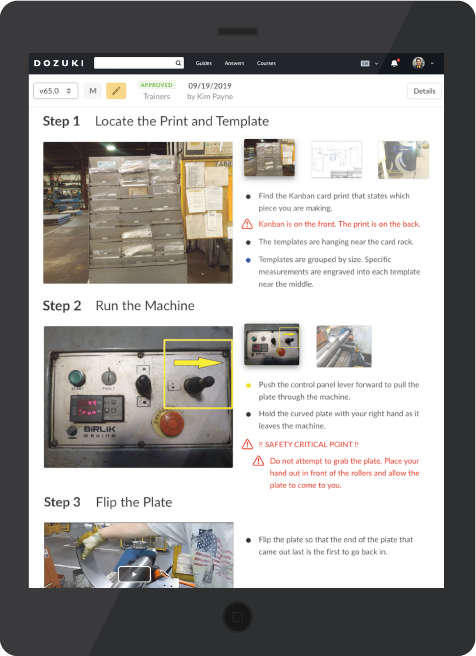

Digital Work Instructions for More Efficient Teams

Digital work instructions are the modern counterpart to SOPs, work instructions, and more. Like Dozuki, these tools are purpose built, and help streamline and distribute up-to-date standards.

We built Dozuki to help companies standardize processes in a way that’s intuitive and helps foster a continuous improvement culture.

The features in Dozuki are built for you >

Related Posts

View All Posts

Frontline Digital Transformation

4 Ways Digital Tools Improve Quality

9 min read

Twenty years ago, digital tools were “a thing.” Now they flow through all things. To some degree, every manufacturer is now a digital company. And with the right modern...

Continue Reading

Standard Work

What's Wrong with Standard Work?

8 min read

66% of companies fail in their attempts at Standard Work. This begs the question - what’s wrong with Standard Work? How can a seemingly simple methodology be so challenging...

Continue Reading

Continuous Improvement

Navigating Processes: Standard Work vs. Work Instructions

4 min read

The manufacturing industry is a professional arena with an overwhelming variety of industry terms and acronyms. We’ve tried to make a list of the most common Lean terms...

Continue Reading