Frontline Digital Transformation

6 min read

Top Challenges Impacting the Frontline Workforce

Even with advancements in technology and automation, the frontline workforce remains essential to modern manufacturing operations. In fact, 72% of factory work is still performed by people.

This means that operators, technicians, and line managers are all your biggest operational risks.

Manufacturing organizations have the same goals — reduce waste, improve quality, increase efficiency, etc.

But operational excellence is an evolving target.

With the generational shift happening in the frontline workforce, manufacturing employees are facing a new set of challenges that directly impact these goals in unique ways. It’s time to understand the needs of the frontline workforce and how new strategies can empower them to perform their best.

Recruitment

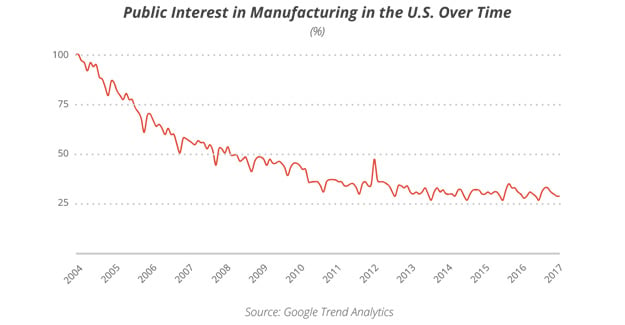

Manufacturing has a perception problem. Overall interest in manufacturing has decreased by over 70% since 2004, according to Google Trend analytics.

Why? The general public still sees the industry as a dirty, dead-end career. This makes it difficult to attract top talent and fill empty roles.

In combination with rising retirement rates, this has created a shortage of skilled labor on the frontline workforce, and this gap impacts manufacturing operations in a major way.

The average U.S. manufacturer is losing an estimated $3,000 per existing employee, due to the talent shortage. Simply filling open positions has a huge impact on frontline performance and operational costs.

Retention

Today’s workforce only stays with their employer for an average of 2.8 years.

For the manufacturing sector, it’s even less.

This means less time to onboard, less time to train, and less time to take all that knowledge and improve upon existing skills.

Plant managers are in a constant game of catch-up, backfilling positions, and spending valuable time and resources to train new hires.

Training and Upskilling

Due to high retirement and turnover rates, the traditional ways of passing down knowledge via 1-on-1 training are no longer viable. There simply aren’t enough senior employees to train and mentor new hires.

Effective training and knowledge management strategies are among one of the best ways to help frontline employees because they accelerate time-to-competency and allow for easier upskilling.

For manufacturers that need to hire and train fast, traditional training methods are a bottleneck for scaling training programs.

Over 55% of manufacturers agree that better training methods are the best way to reduce quality costs. Investing in frontline training is an investment in quality and your bottom line.

Downtime and Equipment Failure

Downtime still remains one of the most costly problems on the factory floor. Broken equipment can rack up millions of dollars in costs and create serious downstream problems.

Whether it’s not following proper maintenance procedures, improperly trained operators, or a lack of troubleshooting knowledge, the root cause of machine downtime is still human-centric.

By providing more resources for frontline employees to be better trained and solve problems as they arise, companies can save millions in operational waste and increase customer satisfaction.

Empowering the Frontline Workforce

While the manufacturing industry has seen a lot of progress, there is still plenty of opportunity for growth. Many companies have begun the journey to digital transformation but lack coherence between strategies, tools, and frontline needs.

New digital technology can help provide modern ways for the incoming workforce to engage with their work and support employee performance.

Even though modern digital tools promise exciting results, they can’t be successful if the people using these tools aren’t on board. 97% of transformations fail when they don't engage line managers and frontline employees.

Operators and line managers will be the most in-tuned with the unique challenges impacting your business. Take the time to learn about the daily challenges that your frontline workforce faces and involve them in digital strategies early on.

Empowering the frontline workforce isn’t about pushing new technologies to the factory floor. It’s about taking a collaborative approach to supporting the needs of your most valuable assets — people.

Topic(s):

Frontline Digital Transformation

Related Posts

View All Posts

Training

Why HR Shouldn't Manage Your Technical Skills Training

6 min read

Amid the Silver Tsunami, HR departments are hustling to onboard and fill personnel gaps, but they can’t predict the evolving demands of your operations. Manufacturing...

Continue Reading

Frontline Digital Transformation

Connected Workforce | What Is It & How Does It Benefit Companies?

20 min read

One of the best ways businesses can get ahead and remain competitive is to embrace the available tools. And right now, that means implementing a connected workforce. Table...

Continue Reading

Frontline Digital Transformation

The Most Common 8 Wastes of Lean Manufacturing & How to Manage Resources

23 min read

Manufacturing is all about making the highest quality products at the lowest cost. Reaching that goal means searching for and eliminating causes of wasted time, wasted...

Continue Reading