Continuous Improvement

6 min read

What is Standard Work?

Lean operations and manufacturers have used Standard Work for decades, yet many companies lack clarity when it comes to this fundamental lean methodology.

How is Standard Work different than standardization? How does standardization enable continuous improvement? In this deep dive, we’ll breakdown the basics of what makes Standard Work, work.

The Current Best Practice

Standard Work is defined by Toyota as a detailed definition of the current best practices for performing a process. The term ‘current’ is key—it means that the "standard" isn't fixed, it should always be improved upon. In this sense, standards (or standardization) are only one part of the methodology. These standards are the baseline, but must be able to change in order to drive improvement.

Standard Work - a detailed definition of the current best practices for performing a process

Using continuous improvement, the quality and efficiency of a process will improve—along with the standards—over time. This is a key driver for both operational advancements and efficiency gains.

Is Standard Work a Contradiction?

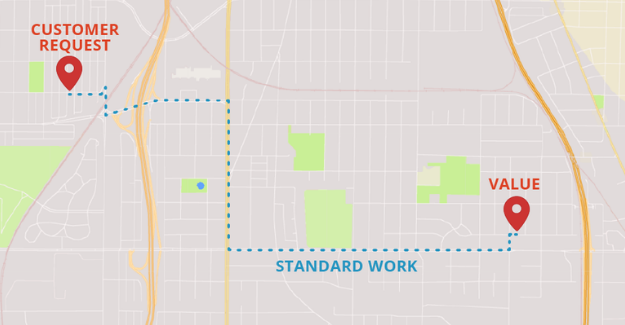

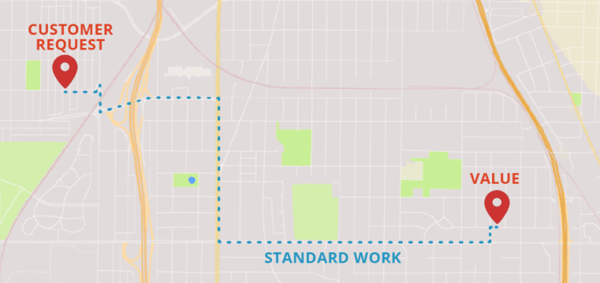

If our starting location is a customer request, and the final destination is delivering value to the customer, Standard Work should provide the most efficient route to get there. In short, Standard Work is the least wasteful way to deliver value to the customer. The word ‘standard’ seems to imply that these documented processes remain static and unyielding when in reality, standards are anything but. The least wasteful way to deliver value to the customer should always be improving. That’s because Standard Work exists to change — a constantly evolving baseline.

Much like the standardized processes documented at work, the route provided by your GPS might have been useful at first, but over time you’ve learned how to do things better. You likely haven’t followed a guided GPS route to commute to the office in some time. Presumably, you’ve learned to take a certain backroad when traffic is heavy, or know that staying in the left lane is faster on one street and then slower on another.

Standard Work Drives Continuous Improvement

Kaizen is an ancient philosophy adopted by Japanese manufacturers to drive a culture of continuous improvement. Literally translated it means “small change,” but its impact is anything but. Kaizen states that big problems can be solved by making incremental improvements over time.

Standard Work serves as a framework to facilitate and record these small changes in a formal way. The benefit is that standardization allows for the distribution of knowledge and progression across a workforce, enabling everyone to enter a mindset of continuous improvement and Kaizen.

"In order for protocols (standards to continue to improve, you have to have a workforce that's thinking, "What small step could I take today to improve the process or product?" Standardization allows everyone to look for incremental ways to make improvements, even as you formalize the process."

Dr. Robert Maurer, "The Spirit of Kaizen"

Create Standards for All Types of Work

Contrary to popular belief, all work can implement some aspect of standardization; and by doing so set a baseline for improvement and quality. While highly repetitive tasks such as assembly procedures easily benefit from standardization, even work that is creative in nature can be standardized.

Take a painter for example. While the elements of actually creating a painting are unique to creative decisions made by the artist, many surrounding processes can still be standardized, and therefore improved. Setting up the canvas, the cleanup/teardown process, quality checks, all fall within the purview of standardization.

Similarly, unique processes in manufacturing environments can benefit from standardization as well. Commonly performed tasks such as setup/changeover process, lockout/tagout procedures, safety procedures — all can benefit from the Standard Work methodology.

The Endless Benefits of Standard Work

Without Standard Work, true continuous improvement can't exist because companies risk backsliding to inaccurate or outdated procedures. As such, this foundation of lean has numerous advantages beyond process consistency.

Make Waste More Visible

Illustrate process inefficiencies and allow wasteful activities to surface.

Train Employees More Effectively

Help new employees understand processes quickly and become less reliant on job-shadowing or in-person training.

Eliminate Tribal Knowledge

Reduce the strain of employee attrition and communicate best practices effectively.

Reduce Defects and Process Variation

Give employees a clear understanding of where their actions deviate from the set process.

Increase Agility and Scale Faster

Rely on documented standards to scale procedures and train new employees quickly; freeing up valuable resources to focus on growing your business.

Streamline Problem Solving

Give team members an equal understanding of the current state and how changes will affect process workflow.

Improve Morale and Promote Innovation

Contextualize process improvement ideas by creating a baseline for how feedback is given, assessed, and implemented.

Reduce Scrap Waste & Prevent Rework

Use standards to provide an accurate account of the materials quality levels needed to maintain proper workflows.

Lower Operational Costs

Assess where process bottlenecks exist and clearly define the minimum work in progress (WIP) to maintain efficient flow.

Increase Customer Satisfaction

Ultimately, customers will benefits from a higher and more consistent product quality delivered by the process improvements standardization has generated.

Related Posts

View All Posts

Standard Work

How to Reduce Changeover Time with Standard Work Instructions

8 min read

Many manufacturers see reducing changeover time as a golden opportunity to improve operational efficiency and reduce waste. For good reason, a simple reduction in changeover...

Continue Reading

Standard Work

What's Wrong with Standard Work?

8 min read

66% of companies fail in their attempts at Standard Work. This begs the question - what’s wrong with Standard Work? How can a seemingly simple methodology be so challenging...

Continue Reading

Standard Work

11 Benefits of Standard Work

5 min read

Taiichi Ohno, a founder of the Toyota Production System (TPS), had this to say about Standard Work, “without standards, there can be no Kaizen.” As the foundation for all...

Continue Reading