Work Instructions

5 min read

Electronic Work Instructions in Industry 4.0

How do electronic work instructions factor into Industry 4.0 and your digital transformation strategy? With advancements in technology, it’s time to reevaluate how these digital systems can improve your manufacturing operations.

The capabilities of electronic work instructions (EWI) have evolved alongside Industry 4.0. Companies need to be aware of these advancements in order to keep pace with competition, reinforce standards, and implement a continuous improvement culture.

Electronic Work Instructions in Industry 4.0

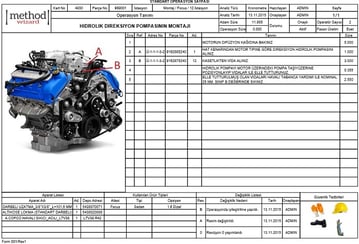

A digital system designed to standardize, distribute, and improve processes; while leveraging human insights and work in conjunction with production management tools and other technologies.

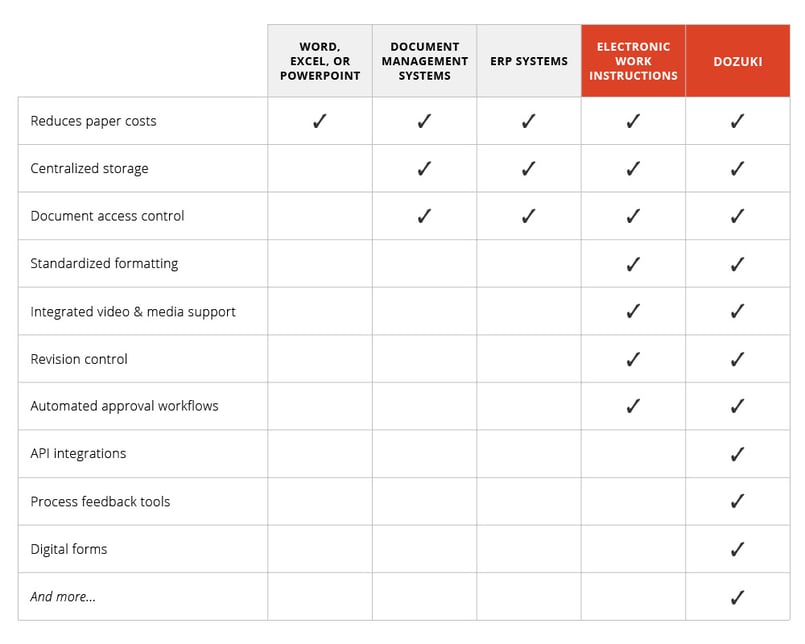

Generic or non-specialized digital systems can carry many of the same problems as their paper-based counterparts. An effective electronic work instruction system captures organizational knowledge and enables companies to:

What Electronic Work Instructions Are Not

In reality, what qualifies as EWI can vary quite a bit. Some tools are broad, flexible platforms that require dense technical knowledge. Others are simplified documentation tools that must be combined with a handful of other generic tools, in order to get the job done.

Neither of these situations are ideal.

Even though your organization is using a digital tool to document and store information, better alternatives may exist. A system that is too flexible or tries to do too much will eventually become cumbersome and unsustainable. A system that’s too simple or not designed with the needs of manufacturers in mind, won’t be successful as Industry 4.0 continues to evolve.

Document Management Systems (Digital File Cabinets)

Document management systems, like Sharepoint, work by storing documents in a shared digital location. Much like a library, files are checked out or rented when they need to be changed; making them either unavailable or outdated for large portions of time.

Storing documentation electronically is a step in the right direction, however, housing digital files on a computer can carry the same problems as physical file cabinets. Managing documents online can be equally ineffective if that same system doesn’t control revisions, increase accessibility, or provide a framework for improvement.

Word, Excel, or Powerpoint

Word was designed to write memos, college essays, and reports — not work instructions. Just the same, generic tools like Powerpoint and Excel weren’t designed with the needs of manufacturers in mind.

These tools aren’t inherently bad, but they are too generic and flexible; making consistency and standardization the biggest problems.

We commonly see companies with numerous versions of their “standard” operating procedures—creating confusion regarding what the true standard is. The result is messy documents and instruction quality that varies from author to author.

These systems also don’t have a standard way to implement document control, meaning that companies must use an additional system to manage access and revisions.

ERP Systems (Enterprise Resource Planning)

Commonly described as the central nervous system of a business, ERPs connect planning, purchasing, inventory, and more. ERP systems are often conflated with, or misused as, work instruction software because they both help manage similar workflows. This represents a disconnect between management activities and the work being done on the floor.

While ERPs manage the workflow of business, electronic work instructions manage how work is done. If ERPs are the organization’s nervous system, then your system for EWI is the brain; storing and revising tribal knowledge for how work is performed.

As the organization learns of better ways to execute a given procedure, the EWI learns with you, by updating and distributing the improved process knowledge to the people who need it.

Pro Tip: Dozuki has an incredible API that allows companies to seamlessly integrate data from ERPs and other business tools with their work instructions.

Electronic Work Instructions in Industry 4.0

Industry 4.0 has been hailed as the next “Industrial Revolution.” In it, complex systems of digital devices communicate with one another and their human counterparts, making factory processes visible and controllable from anywhere.

Redefining work instructions for this dynamic and innovative work environment will allow companies to maintain a competitive edge and approach the future with confidence.

Related Posts

View All Posts

Work Instructions

4 Signs Your Work Instructions Need an Upgrade

6 min read

Knowing when to make the transition to a better documentation tool is a tough question to answer. The short answer is that there is no short answer. In Industry 4.0, a...

Continue Reading

Continuous Improvement

How to Scale Technology Across Manufacturing Operations with 3M

39 min read

Most manufacturing companies don't have people dedicated to evaluating and deploying modern tools. At best, IT or HR takes responsibility for new technology and doesn't have...

Continue Reading

Continuous Improvement

Implementing Continuous Improvement with Dozuki

3 min read

Is your company interested in reaping the benefits of continuous improvement (transparency, efficiency, cost reductions, etc.) but aren't sure where to begin? Dozuki has you...

Continue Reading